Kapton Heaters-UL Listed, Kapton Film Heaters, Flexible Heaters

UL Listed Kapton (Polyimide) Film Heaters & Custom Kapton Heater Circuits For-3D Printers, Electronic Components, ATM's & Printers

kapton-flexible-heating

What is Kapton™ (Polyimide) Film? Guide.

.jpg)

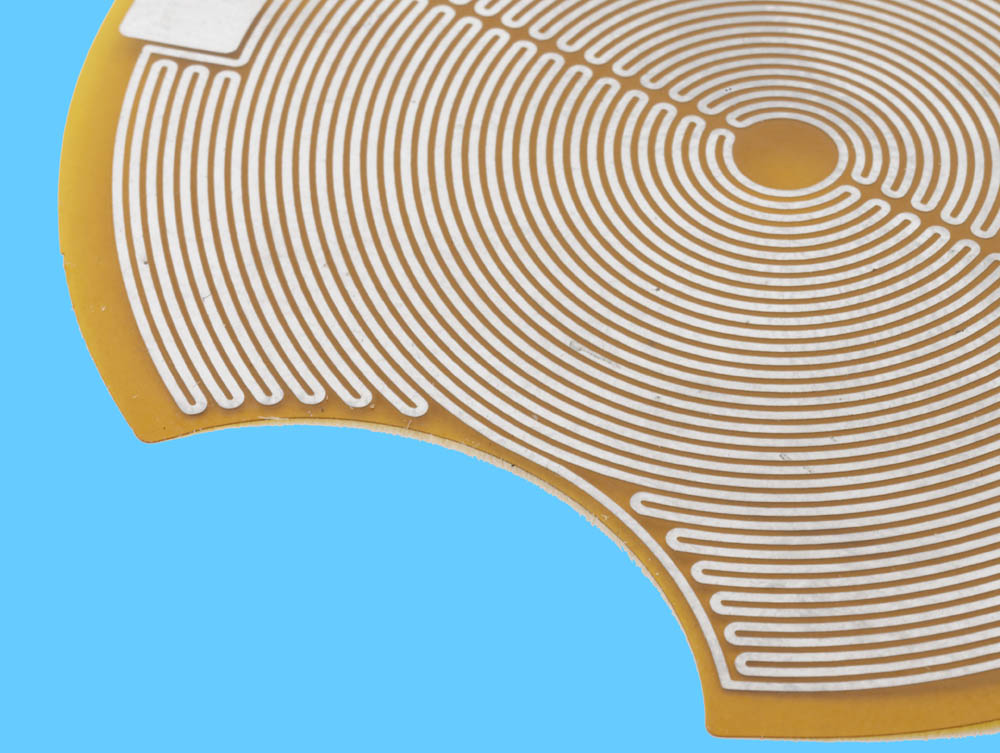

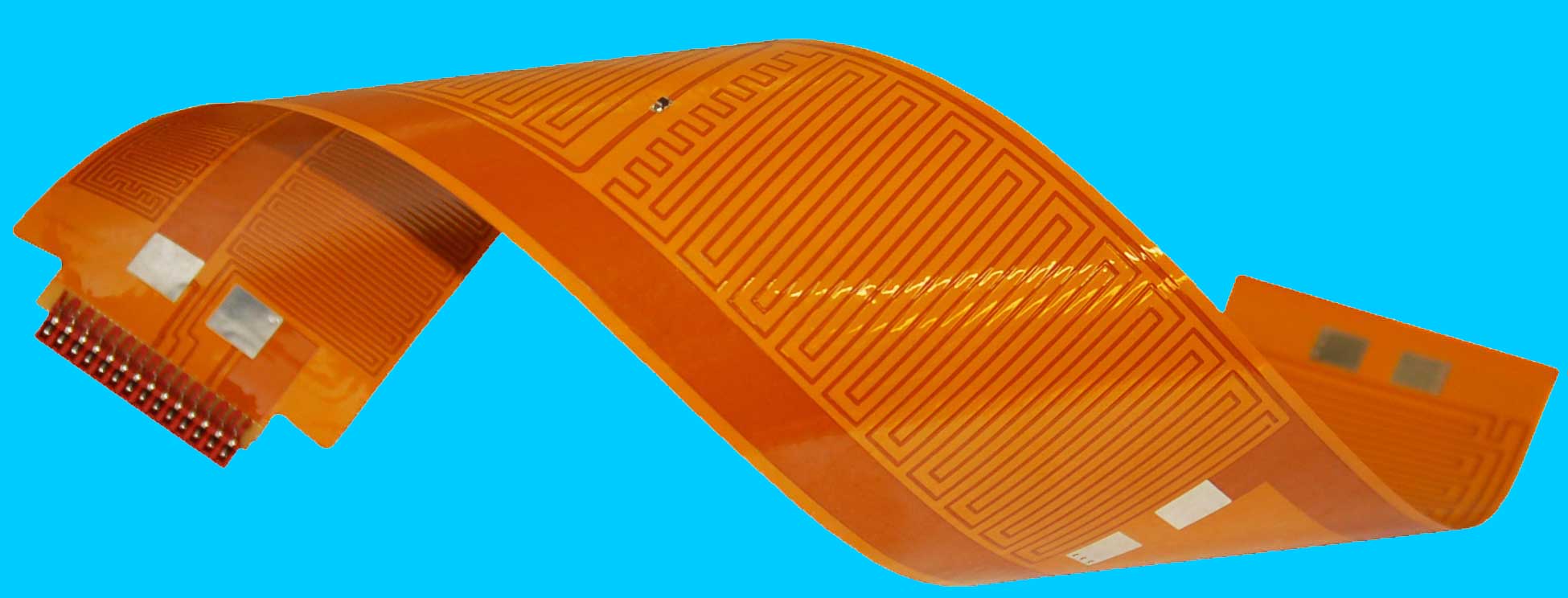

UL Listed Custom Etched Foil Kapton Heaters

Kapton Polyimide Heaters

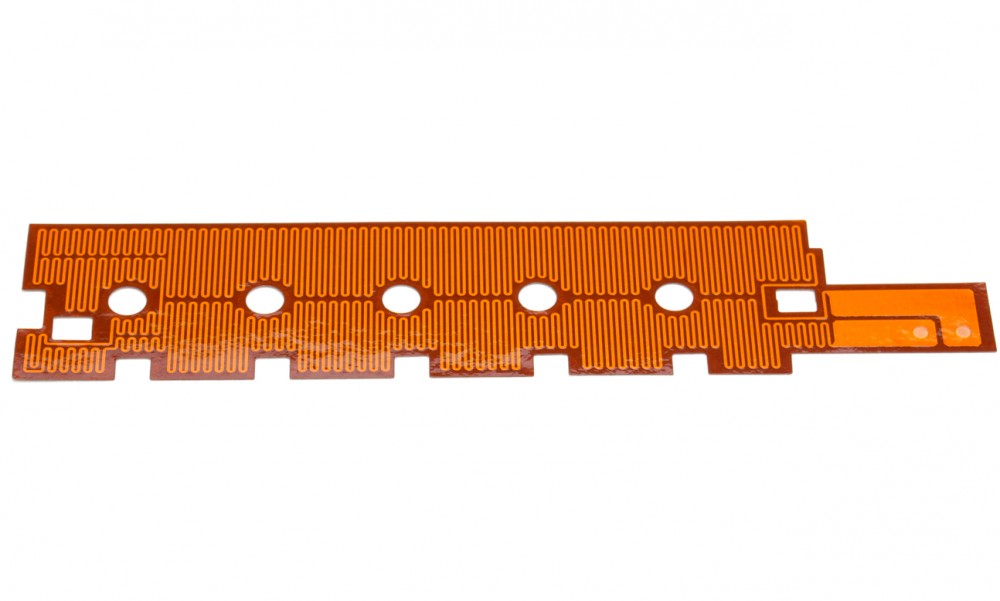

Kapton Heater Circuits with Holes

Review, Product Description and Benefits of Bespoke Kapton (Polyimide) Film Heaters:

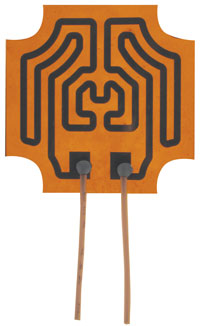

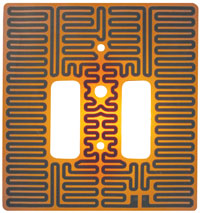

Kapton polyimide heater circuits are custom manufactured using etched foil track technology. With etched foil kapton (polyimide) heaters, chemically etched resistive foils are used. The advanced computer designed etched foil circuit pattern is then laminated or bonded between two sheets of polyimide insulating film.

Benefits of custom/bespoke and UL listed kapton (polyimide) etched foil film heaters are as follows:

Curled Kapton Polyimide Film Heater/Thermal Circuit

Kapton Film Circuits-Specifications, Manuals, Technical Letters & Tips:

| Kapton Polyimide Flexible Heaters Brochure | |

| FAQ's-Kapton Polyimide and Silicone Heaters-Brochure.pdf |

Due to the above material properties and benefits, custom/bespoke kapton (polyimide) film heaters have a vast number of applications. It is this combination of useful properties at temperature extremes that makes Kapton® a unique industrial material. Listed below are just a few of the applications where kapton heater circuits are used.

- Medical applications, typically requiring clean and sterile environments - Medical Imaging, Medical Diagnostic Instruments and Analyzers, MRI Equipment

- All types of heating applications for electronic components - LCD displays, photocopiers and photographic equipment, ATM's, computer equipment, 3D printers

- Evironmental control and maintenance of electronics - in telecommunications equipment (such as antenas, microvave repeaters and back-up battery systems), electrical panels and enclosures

- Heating of Aerospace/Defence Instrumentation where low outgassing properties are required - Aviation instrumentation and personal comfort heating, Satellites, Spacecraft, Satellite Dish

- Industrial Applications such as heating of Electronic Enclosures, Heaters for motors, cold storage equipment, freeze protection

- Transportation - kapton heaters for Over the Road Truck and Railcar Freeze Protection, Battery and Oil Heating, Auto and Motorcycles

- Applications in the Energy Industry - Fuel Cells, Battery Systems, Power Meters, Transmission Switches

- Printing Equipment Industry, Optical and Photograghic equipment, cameras

TEMPERATURE CONTROL FOR KAPTON (POLYIMIDE) FLEXIBLE HEATERS:

NPH kapton polyimde heaters can be supplied with factory fitted sensors and switches to suit all types of instrumentation. Available from stock are PT100's, J, K and T type thermocouples, bi-metal thermostats and thermal fuses. We also fit customer specified thermistors and other resistance temperature devices as well as extruded pockets for customers to fit their own sensors. Separate mechanical or digital thermostats can be supplied for process control.

Request For Quotation - RFQ

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide