Quartz Immersion Heaters With Stainless Steel Heating Element & Teflon (PTFE) Fluoropolymer Tank Acid Heaters Guide For Industry

Immersion Heater-Over The Side.jpg)

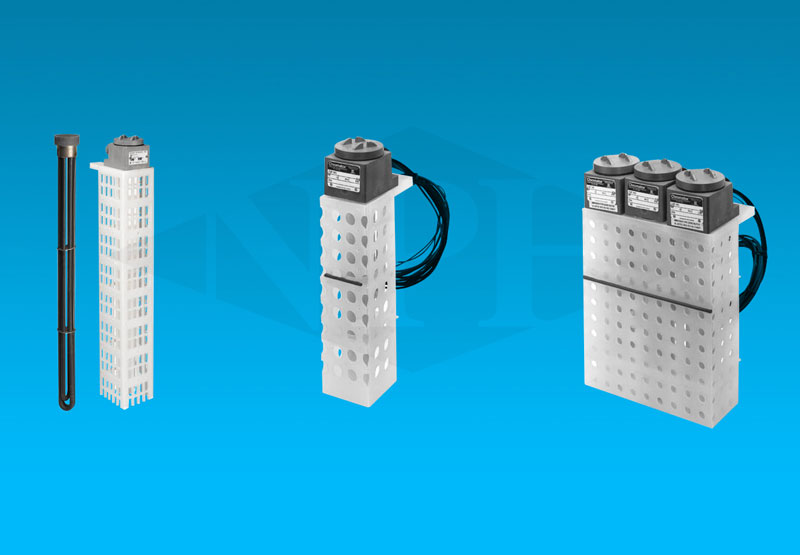

Product Description Guide: Quartz Immersion Heaters with Metal Elements:

National Plastic Heater's quartz immersion heaters are suitable for most acidic chemistries or solutions. They are composed of metal tubular elements which are encased within a heavy wall quartz outer sheath. Quartz chemical over the side heaters are suitable for all acid solutions except those containing hydrofluoric or fluorides. Their standard watt density is around 40 W/sq. in. for mild acids. Low watt density quartz over the side immersion heaters of 20 watts/sq. in. is recommended for heat sensitive or heavy acid solutions such as for nickel plating, electro-polishing or phosphoric acid. NOT recommended for alkaline or caustic solutions. They are available in single tube or three tube heater units which include a preset over temperature control.

Teflon immersion heaters have a .030 wall of Teflon covering a metal element. This heater has a positive metal ground and superior anti corrosive characteristics that make it ideal for immersion into solutions like HCL, HF, Nitric or Chromic Acid.

Quartz immersion heaters and Teflon immersion heaters over the side construction enable easy installation and replacement. Liquid tight terminal covers prevents entry of liquids. Thermostats or high limit thermal fuses are available as options and prevent heater damage due to loss of liquid or low liquid. Titanium immersion heaters are available that are highly corrosive resistant and can withstand harsh chemicals and environments.

Features and Benefits

Superior Chemical Resistance: For use in most aqueous acidic plating solutions and pickling tanks. Check solution recommendation chart or with your chemical supplier for proper sheath material selection.

Materials of Construction: Heavy wall quartz sheath with replaceable metal element and polypropylene guards (complete assembly).

Outstanding Performance: Watt densities of 25 watts per square inch (4 w/cm2) ensure long service life.

Corrosion resistant Head: Vapor resistant, flame retardant polypropylene terminal enclosure with 3-foot (.9m) flexible PVC liquid tight conduit.

Safety Features:

- Grounded construction

- Thermal protector built in. Replaceable P1 fuse standard for solutions up to 180°F (82°C).

Certifications: UL listed to U.S. and Canadian safety requirements (less than 4000 watts), and 600 volt CSA only.

Sizes: 500 watts to 10,000 watts.

Voltages: 120 to 600 volts. Single phase standard, three phase available.

Teflon (PTFE) Sheathed Immersion Heaters-Product Description Guide:

Our fluoropolymer (PTFE) immersion heaters are compatible with virtually any chemistry and are available in sizes up to 18 kilowatts, single or three phase. We offer a large variety of standard and custom configurations for over-the-side and tank bottom installations, and low profile custom designs are also available. Rigid and flexible risers available. Our screw plug and flange heaters are manufactured in sizes from ½-inch screw plug (100 watt) to 6-inch flange (18 kW). Thermal overtemperature protection standard (except screw plug), and we offer rigid and flexible risers. The vast majority of our immersion heaters are cULus and CE.

Quartz and Teflon Immersion Heaters: Specifications, Manuals, Technical Letters & Tips:

|

|

|

|

For applications ranging from water to severely corrosive chemistries, these products include: electric immersion heaters, heat exchangers, temperature and level controls. Materials of construction: fluoropolymer, titanium, quartz and stainless steel. Certifications: cULus and CE.

- Nickel Plating

- Corrosive Chemical Heating

- Chrome Plating Tanks

- Cleaning and Rinsing Tanks

- Electropolishing

- Acid Solution Plating Tanks

Standard Construction Features:

Elements Materials â€

Number of Elements in Flanges

Element Diameter †Watt Density †Flange - Materials - Flange Rating “ Flange Sizes Round Flanges-

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide