Freeze Dry Heaters | Freeze Dryers & Equipment

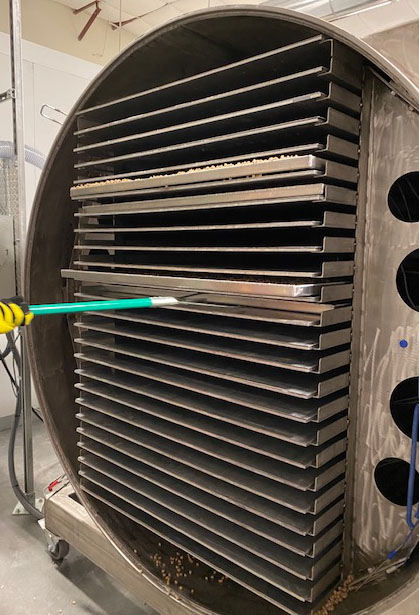

Freeze Dry Equipment With Custom NPH Silicone Rubber Heaters Beneath Trays

Now, available from NPH, custom silicone rubber heaters and technology for the Freeze Dry industry. Freeze drying, also known as lyophilisation or cryodesiccation, is a low temperature dehydration process that involves freezing the product, lowering pressure, then removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat.

Preserve your garden produce, create the perfect emergency food supply, make camping meals and healthy snacks. Unlike other methods of food preservation, freeze drying does not shrink or toughen the food, and retains flavor, color, and nutrition.

Freeze dryers produce food that looks and tastes better than store-bought freeze dried food. Experience the difference!

Refrigerated, frozen, and canned food just don’t last very long. Freeze dried food will last up to 25 years and does not need to be to be rotated like other foods. Freeze dried food is perfect for home storage.

Nutrition: Freeze drying maintains 97% of the nutritional value of the food. Other methods of preservation, such as canning and dehydrating, use high temperatures that destroy much of the food value.

Freeze drying works great for fruits and vegetables, but unlike other options, it also perfectly

preserves meat, fish, dairy, eggs, ice cream, and even fully-cooked meals.

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide