Custom Flexible Silicone Heaters and Polyimide Thermal Circuits

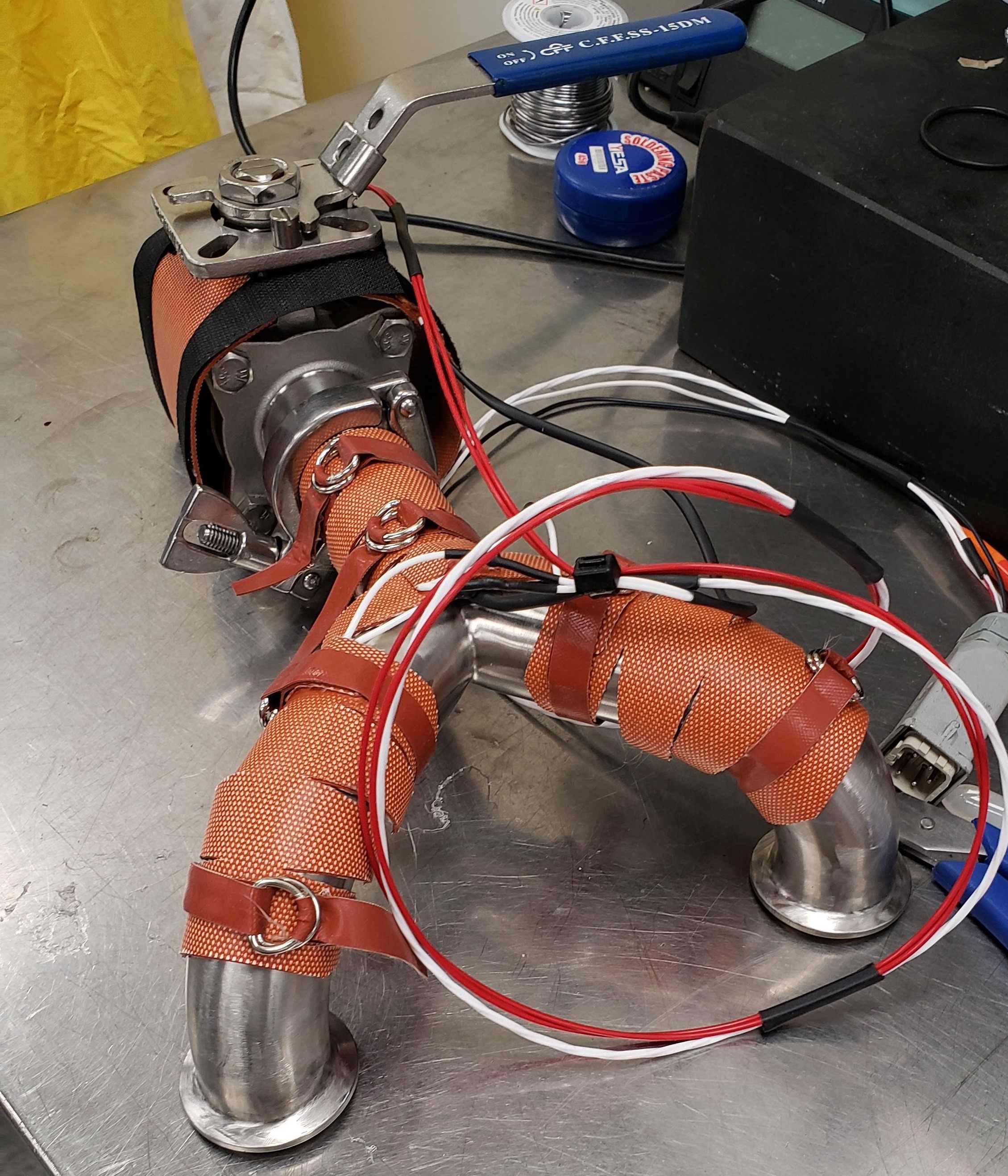

Custom Silcone Manifold Heaters with

D Rings Closure by NPH

Manufacturing of Wire Wound Silicone Rubber Heaters

CUSTOM SILICONE RUBBER AND KAPTON HEATERS - DESCRIPTION

Kapton® flexible heaters offer superior tensile strength

and tear resistance, with precision heat distribution. They are ideal for extreme temperature

environments, from -319°F to +392°F (-195°C to +200°C).

Heaters are in stock standard at 0.0007" (0.2mm) thick and up to 20"x26" (.508m x

.660m) areas. Watt density is 5W/in² (0.8W/cm²) standard, with units

available to 50W/in² (7.8W/cm²). Kapton® is an organic polymer with very

high dielectric capabilities, while providing superior resistance to most solvents, oils, even

radiation. With low out gassing, these heaters are useful in vacuum environments. Etched foil

heating elements, with 12" (305mm) long Kapton or Teflon® leads, are standard. Silicone

leads, as well as custom lengths, cord and plug sets available.

Being transparent, Kapton® film also allows easy visual inspection on the internal structures. Pressure-sensitive adhesive (PSA) backing surface is not standard, but NPH will customize your Kapton® heaters with special adhesives or mounting holes, as the application requires. Mechanical fasteners such as hooks, grommets, spring-loaded latches, snaps and Velcro® patches are also available. Minimum radius flexibility 1/32" (0.88mm) standard with weight of 1 1/2oz/ft² (0.05g/cm²).

Bespoke silicone rubber heaters consist of many layers of silicone rubber sheets that are bonded together through heat and high pressure. A fiberglass grid (which is visible on the surface) reinforces the silicone rubber sheets. It is possible to make the surface of the heaters smooth (i.e. make the grid invisible) by covering the fiberglass with a thin layer of silicone. A uniformly spiraled resistance wire web that covers the entire surface of the heater is embedded within the layers of silicone rubber. This web could be designed such that holes and cut-outs are incorporated on the heater. When silicone rubber heaters are made with a pressure sensitive adhesive backing, a thin layer of aluminum is added prior to the adhesive layer, in order to improve heat transfer and maintain its uniformity. This construction makes silicone rubber heaters an ideal solution to the requirements of many low and medium temperature applications, which do not conform to the standard shapes, sizes and dimensions of band, strip, cartridge, tubular and coil heaters.

Wire Wound-Custom Silicone Rubber Heaters

Using evenly spaced resistance wires laminated between sheets of silicone, wire wound silicone rubber heater mats are ideal for prototyping or problem solving applications. Manufactured to customer specifications they can be made in a limitless range of shapes and sizes. High flexibility can be obtained using tough, robust silicone materials which are finding ever increasing applications in the industry. Silicone's wide temperature range, tolerance of -60 to +230 °C and superb electrical properties give it a distinct advantage over other forms of heating.

Etched Foil-Silicone Rubber Heaters

Computer designed chemically etched foil tracks are laminated between thin sheets of silicone to give precise even heating. Suitable for both low and high volume production etched foil heaters have rapid heat up properties with precise temperature control. Heating solutions are available in a limitless range of etch foil heaters to customer specification for multiple industries. Silicone's wide temperature range, tolerance of -60 to 230°C and superb electrical properties give it a distinct advantage over other forms of heating.

Being transparent, Kapton® film also allows easy visual inspection on the internal structures. Pressure-sensitive adhesive (PSA) backing surface is not standard, but NPH will customize your Kapton® heaters with special adhesives or mounting holes, as the application requires. Mechanical fasteners such as hooks, grommets, spring-loaded latches, snaps and Velcro® patches are also available. Minimum radius flexibility 1/32" (0.88mm) standard with weight of 1 1/2oz/ft² (0.05g/cm²).

Bespoke silicone rubber heaters consist of many layers of silicone rubber sheets that are bonded together through heat and high pressure. A fiberglass grid (which is visible on the surface) reinforces the silicone rubber sheets. It is possible to make the surface of the heaters smooth (i.e. make the grid invisible) by covering the fiberglass with a thin layer of silicone. A uniformly spiraled resistance wire web that covers the entire surface of the heater is embedded within the layers of silicone rubber. This web could be designed such that holes and cut-outs are incorporated on the heater. When silicone rubber heaters are made with a pressure sensitive adhesive backing, a thin layer of aluminum is added prior to the adhesive layer, in order to improve heat transfer and maintain its uniformity. This construction makes silicone rubber heaters an ideal solution to the requirements of many low and medium temperature applications, which do not conform to the standard shapes, sizes and dimensions of band, strip, cartridge, tubular and coil heaters.

Wire Wound-Custom Silicone Rubber Heaters

Using evenly spaced resistance wires laminated between sheets of silicone, wire wound silicone rubber heater mats are ideal for prototyping or problem solving applications. Manufactured to customer specifications they can be made in a limitless range of shapes and sizes. High flexibility can be obtained using tough, robust silicone materials which are finding ever increasing applications in the industry. Silicone's wide temperature range, tolerance of -60 to +230 °C and superb electrical properties give it a distinct advantage over other forms of heating.

Etched Foil-Silicone Rubber Heaters

Computer designed chemically etched foil tracks are laminated between thin sheets of silicone to give precise even heating. Suitable for both low and high volume production etched foil heaters have rapid heat up properties with precise temperature control. Heating solutions are available in a limitless range of etch foil heaters to customer specification for multiple industries. Silicone's wide temperature range, tolerance of -60 to 230°C and superb electrical properties give it a distinct advantage over other forms of heating.

Flexible silicone rubber and kapton polyimide thermal circuits are

extremely versatile and operate efficiently in many environments. Some distinct advantages

of custom silicone rubber and bespoke kapton flexible heaters are:

- Moisture resistance,

- Oil and solvent resistance,

- Chemical resistance,

- Outdoor exposure ,

- Extremely thin profiles,

- Conform to almost any shape.

The particular application conditions of aerospace, medical, composite fabrication, optical equipment and computers often require flexible heating elements. NPH offers a wide assortment of in-stock and custom flexible heaters in kapton® and silicone rubber materials to suit most any of these needs. Silicone rubber heaters permit composite bonding and curing, as well as repair and fabrication operations. Equal length circuits and a cool tab are provided, while a fiberglass reinforced heater cover means long service life and increased durability. Standard watt density is 5W/in2 (0.8W/cm2). All standard heaters are UL Recognized. Many sizes in stock from 6" x 6" to 20" x 20" (152.4 mm x 152.4 mm to .508 m x .508 m).

Custom Silicone Rubber Heaters-Cone Shaped

Custom Kapton Polyimide Heaters

Silicone Rubber Heaters for Flanges & Elbows

Silicone Rubber Heaters for Pipes, Flanges & Elbows-Custom

Removable Silicone Heaters Elbow With Hooks

Removable Silicone Heaters Elbow With Eyelets

Adhesive Tube Warmers (Silicone Heaters) For Contractors, Trades and Construction Industry

Custom Larger Adhesive Tube Warmers

Bespoke Silicone Rubber Heaters with Eyelets Closure Method

Bespoke Silicone Rubber Heaters with Eyelets Closure

Method

Custom Silicon Rubber and Kapton (Polyimide) Heaters: Specifications, Manuals, Technical Letters & Tips:

CUSTOM SILICONE RUBBER and KAPTON FLEXIBLE HEATERS - APPLICATIONS:

- Heating of Electronic Components- ATM's and Photocopiers

- Heating of Aerospace Instrumentation-Satellites and Spacecraft

- Semiconductor Wafer Processing

- Autoclaves, Incubators and Sterilizers

- Vacuum Chambers

- Medical Imaging, Medical Diagnostic Instruments and Analyzers

- Applications requiring a flexible shape or design

THERMAL OR TEMPERATURE CONTROL FOR CUSTOM SILICONE RUBBER HEATERS:

NPH silicone rubber heaters can be supplied with factory fitted sensors and switches to suit all

types of instrumentation. Available from stock are PT100's, J, K and T type thermocouples,

bi-metal thermostats and thermal fuses. We also fit customer specified thermistors and other

resistance temperature devices as well as extruded pockets for customers to fit their own sensors.

Separate mechanical or digital thermostats can be supplied for process control.

How To Order Custom Silicone Rubber and Kapton Flexible Heaters

- Specify length and width

- Specify watts and Volts

- Specify type of temperature control required-Thermocouple, RTD, Pre-Set T-stat etc

- Specify with or without sticky back (PSA-pressure sensitive adhesive)

- Specify holes, notches, cutouts etc.

- Provide drawing and or image or sample when required

- Specify length of leads

- Specify wire wound or etched foil construction design

- Specify type of application and its parameters

- Specify pipe OD (outside diameter) when required

- Specify if factory vulcanization will be required

- Specify if these heaters are to be pre-formed to fit your configuration when required

- Specify prototype and production run quantities required

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide