Review Ceramic Insulated Band Heaters, Custom Knuckle Band Heaters

Review Description Of Ceramic/Knuckle Band Heaters:

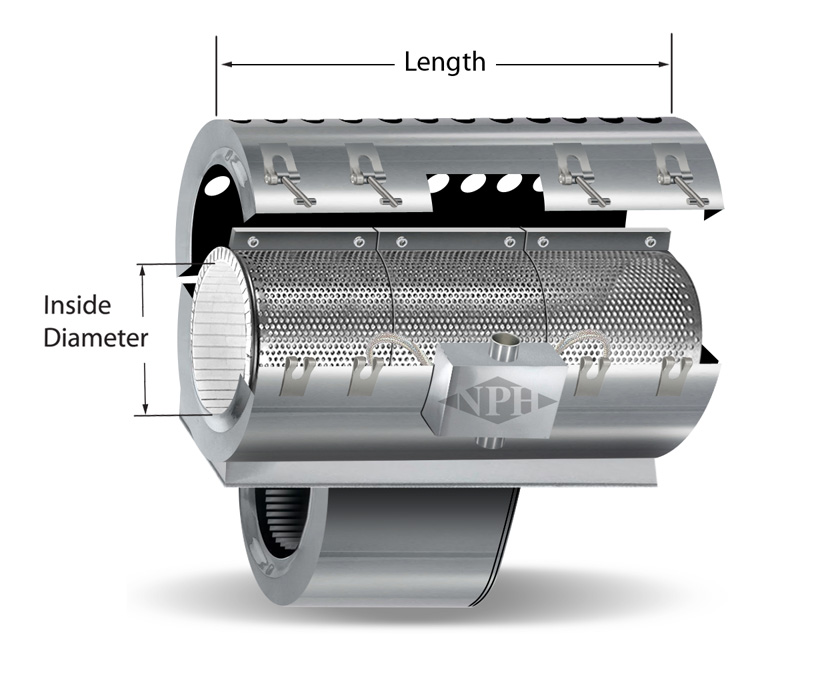

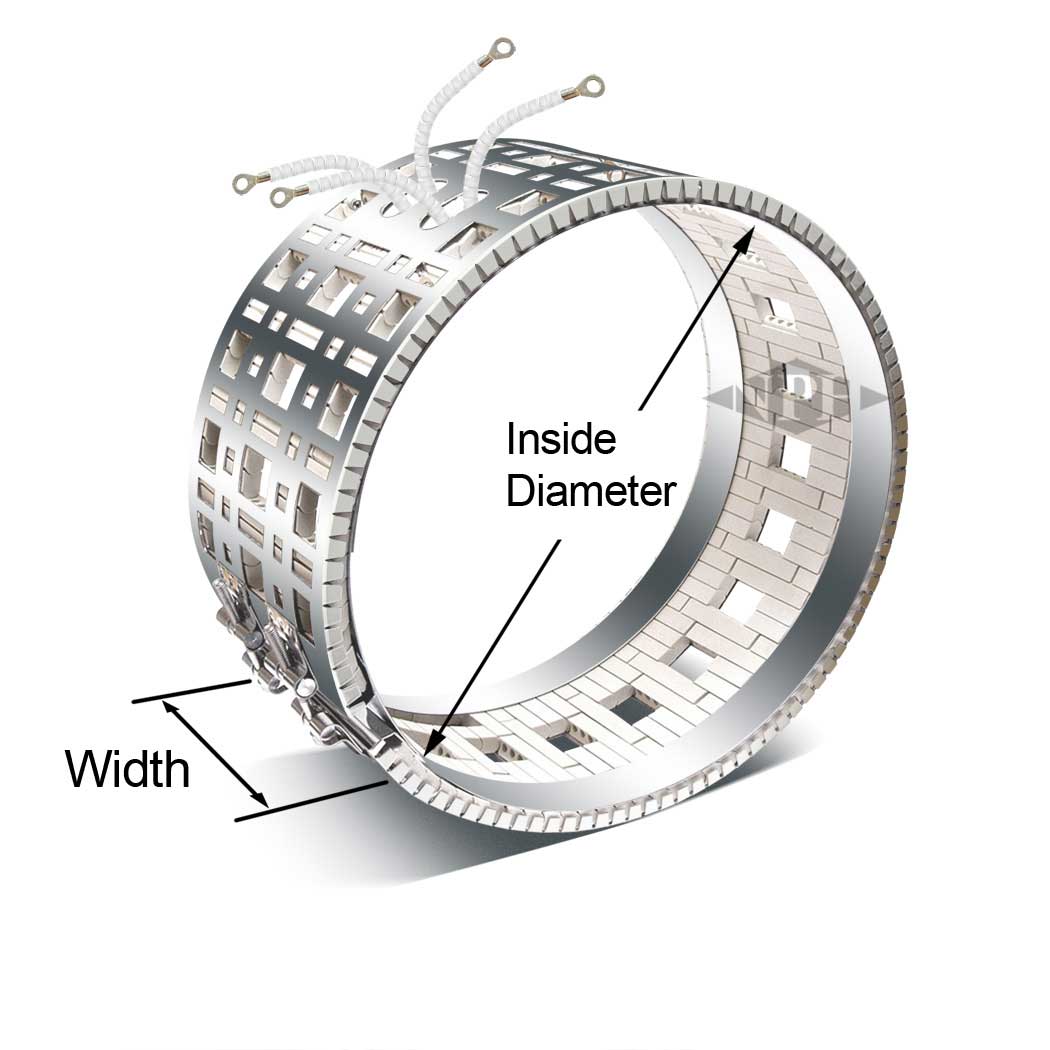

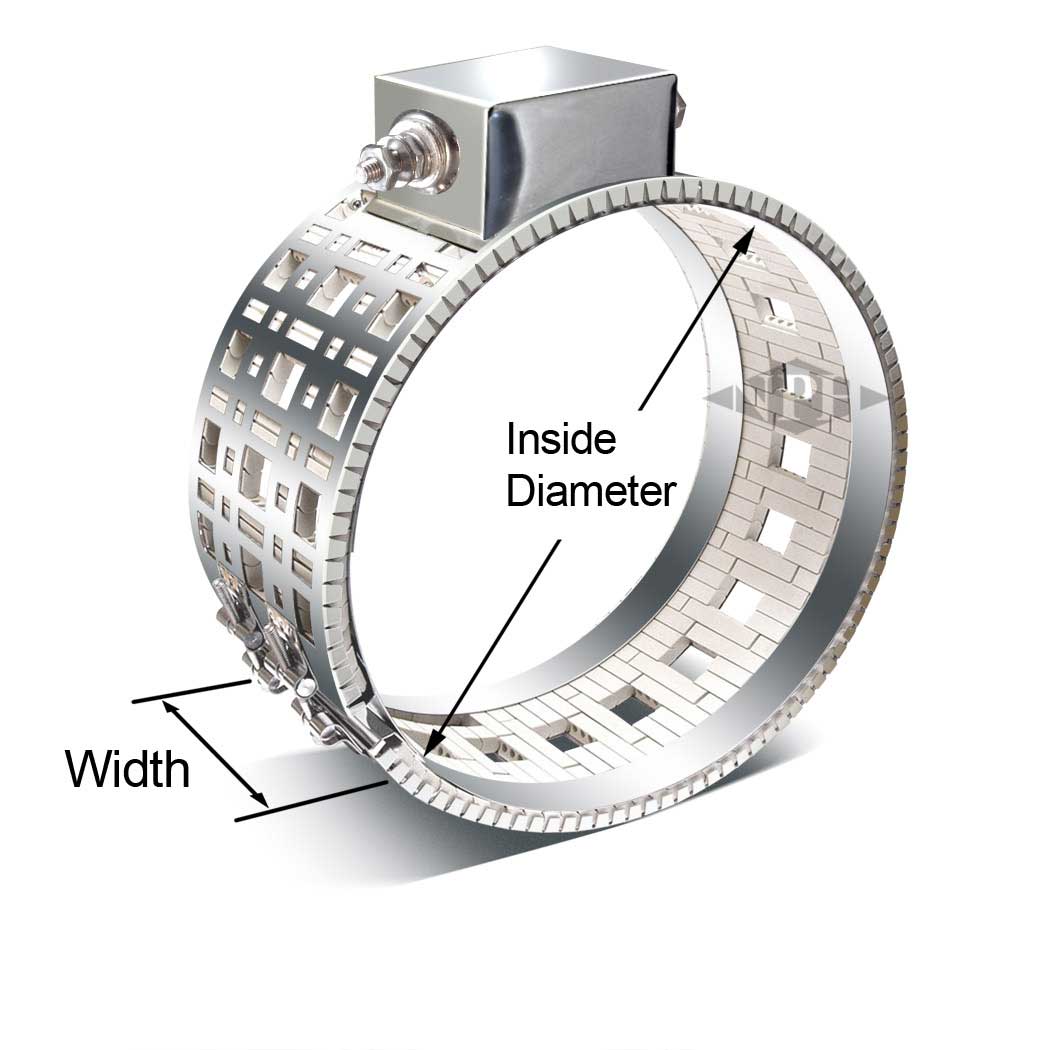

Ceramic band heaters and custom ceramic insulated band heaters or otherwise known as knuckle band heaters are suitable for plastics injection molding, extrusion, blow molding and blown film equipment as well as for other commercial and industrial applications including heating of pipes, cylinders and tanks. Ceramic knuckle band heaters offer lower operating cost - because of superior insulation, less heat escapes to the air and less wattage is required to maintain barrel temperature. Ceramic fiber insulation reduces power consumption by 20% to 30%. Ceramic heater bands offer higher operating temperatures and longer heater life, because all materials used are rated to operate at very high temperatures. In addition, knuckle heaters offer dual heat transfer (heat is transferred through both radiation and conduction) so a near perfect fit is not required as with other heaters, such as mica heaters. Due to the fact that the majority of the heat is going directly to your process, the ceramic band heater gives off significantly less heat to ambient air than a mica band heater.

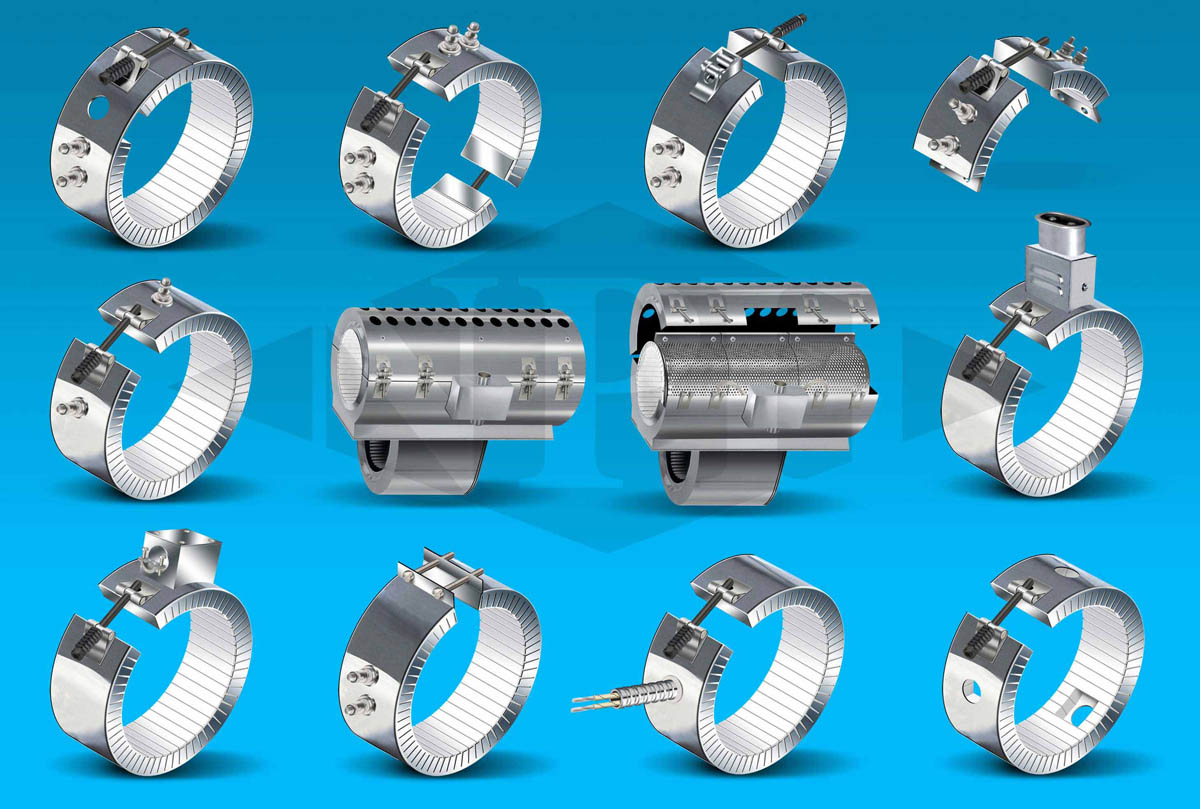

National Plastic Heater provides ceramic band or knuckle insulated heaters with standard and heavy duty insulation options. We also can customize knuckle band heaters with holes, cut-outs and partial coverage options as well as various clamping and termination styles.

Successfully positioned in domestic trade, National Plastic Heater is also engaged in the business of exporting industrial process electric heaters, temperature sensors (thermocouples and rtd's), temperature control panels and solid state relays (SSR's) to OEM's, R & D Specifiers, Plastics and Rubber Industries, Machine Fabricators, Universities and End Users.

Ceramic Band Heaters: Specifications, Manuals, Technical Letters & Tips:

Ceramic Band Heater 1 Pc. Construction, Post -Terminals Style 1

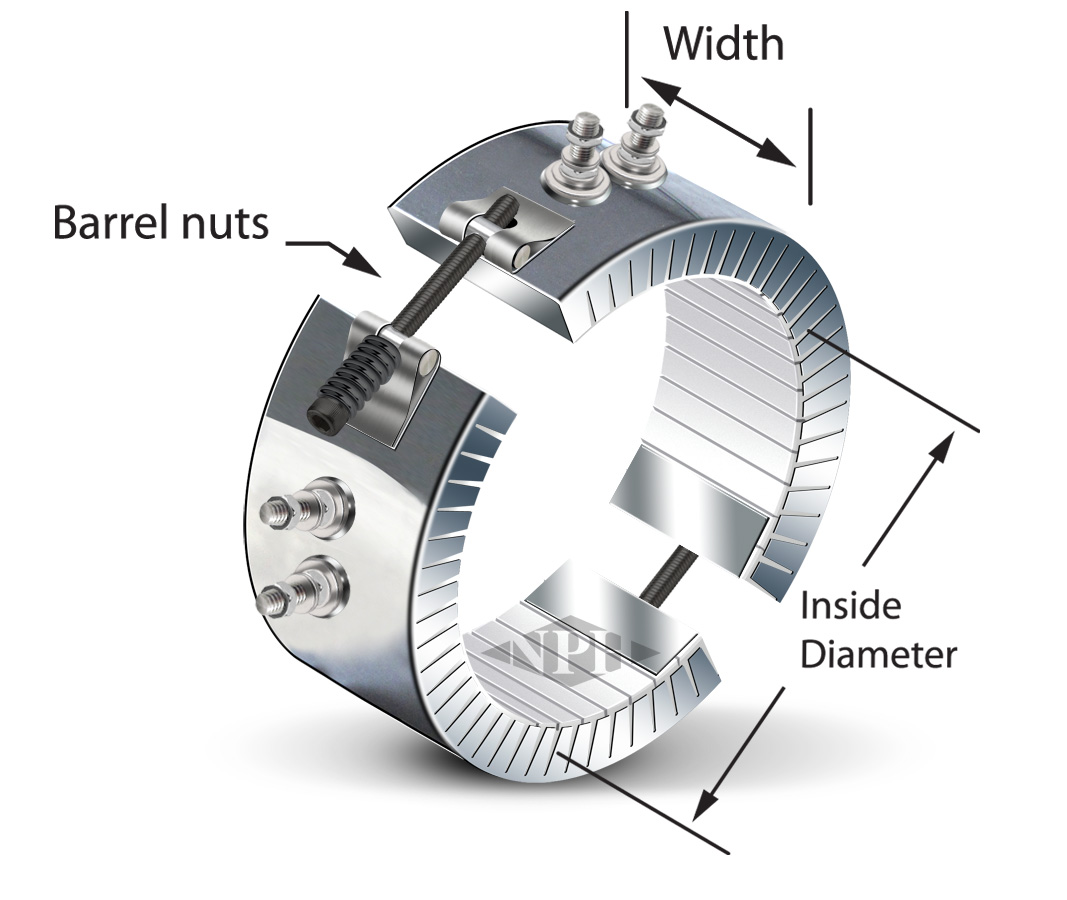

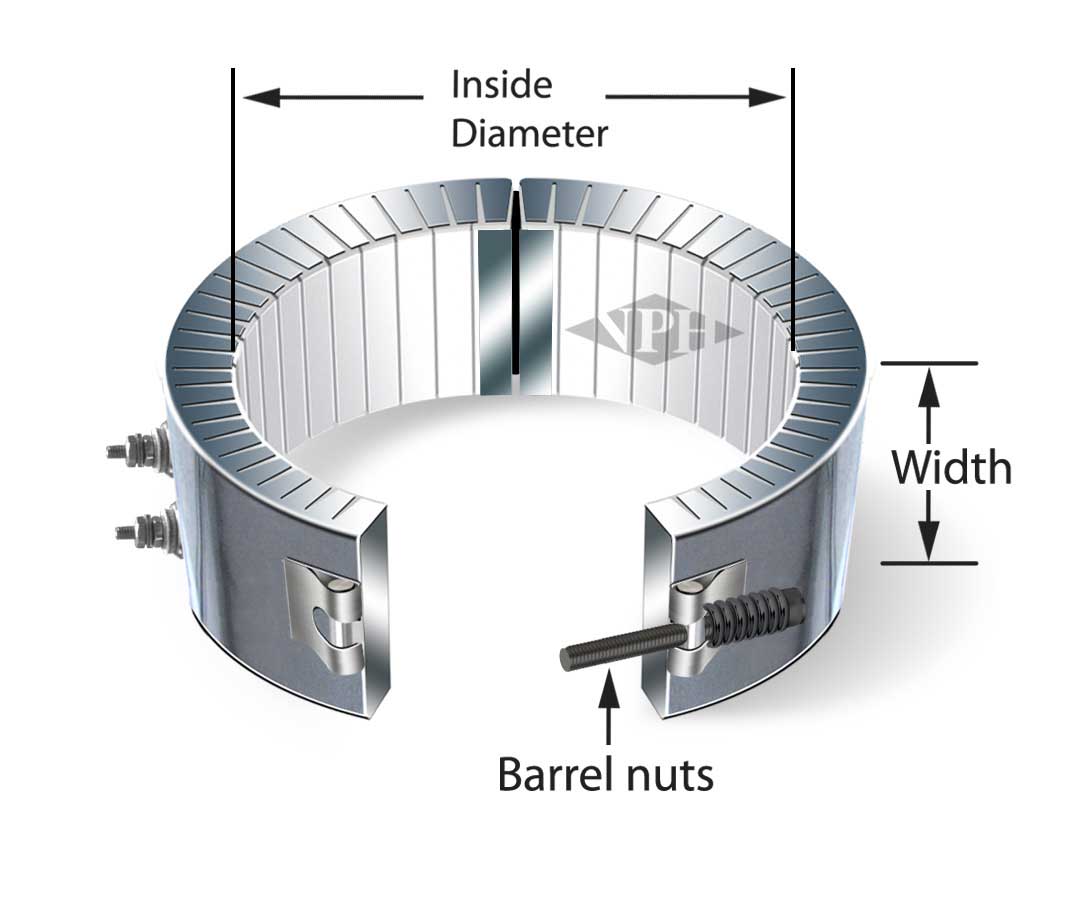

Ceramic Knuckle Band Heater Two Pc. Construction -Style 2

Knuckle Band Heater Partial Coverage Post Terimals -Style 3

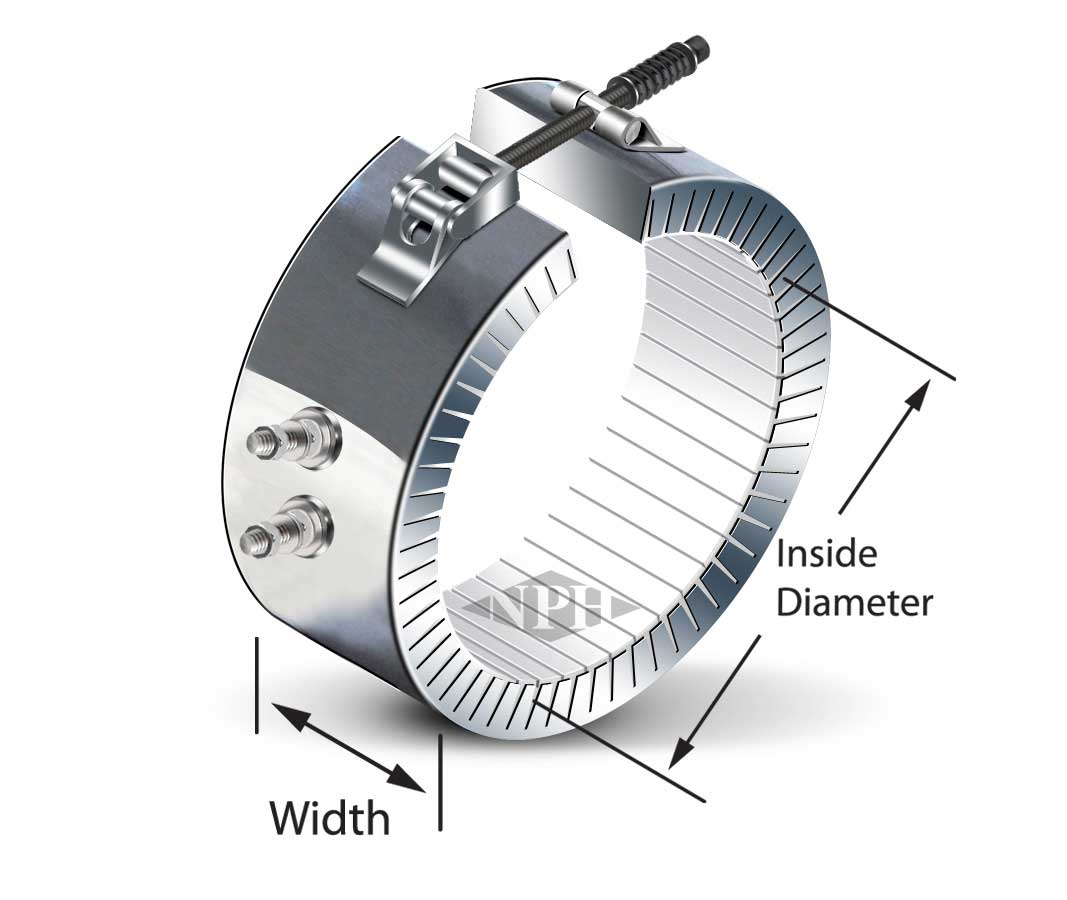

Ceramic Band Heater 1 Pc. Construction, Post -Terminals on Each Side of Gap- Style 4

Ceramic Knuchle Heater 1 Pc. Construction, Post -Terminals on One Side - Style 5

Ceramic Band Heater 1 Pc. Construction, Post -Terminals on One Side Centered at Width - Style 6

Ceramic Band Heater 1 Pc. Construction, with Bent -Up Flange - Style 7

Knuckle Band Heaters- 1 Pc. Construction Post -Terminals Ceramic Caps & Ground - Style 8

European Plug Ceramic Band Heaters -Style 9

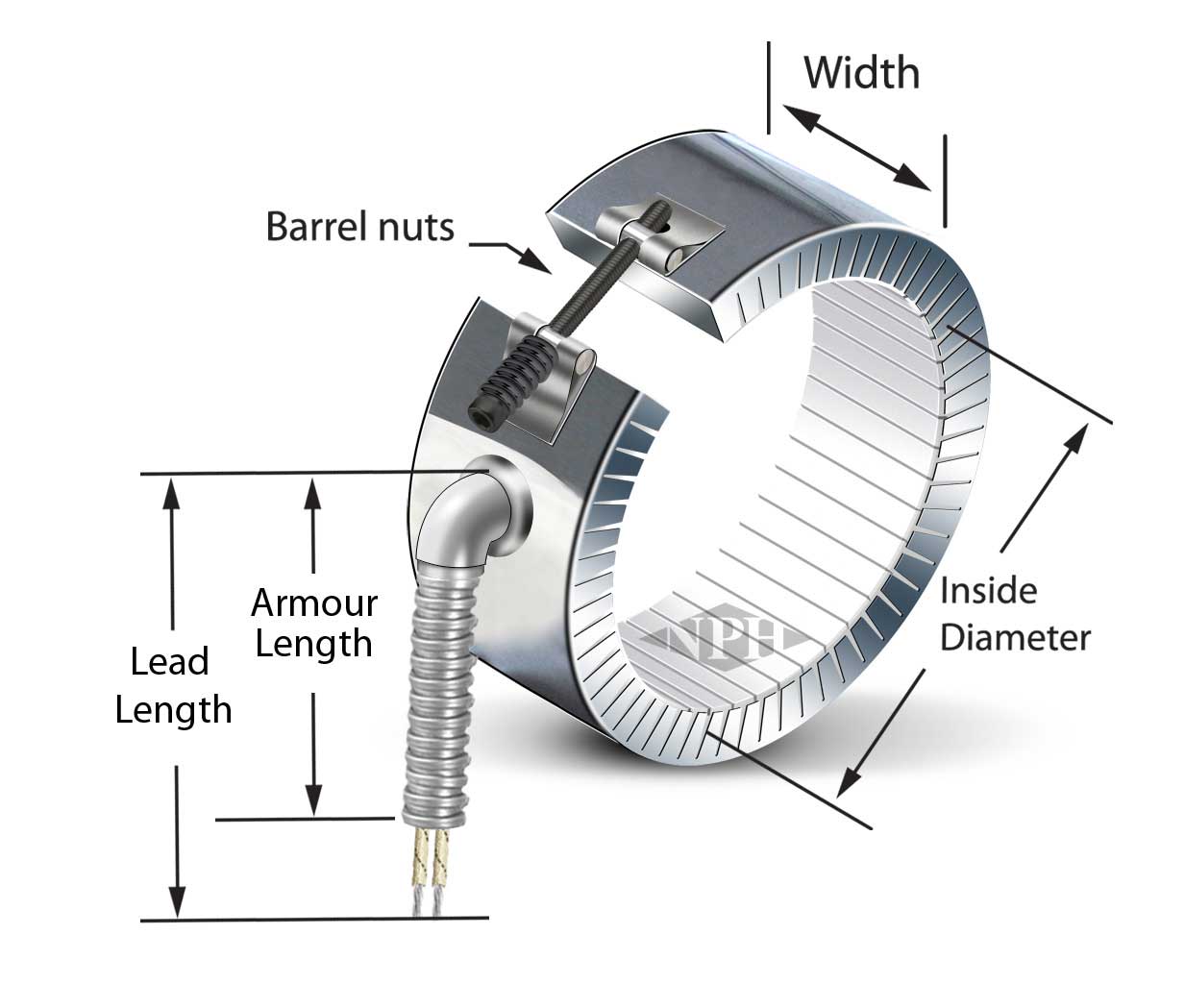

Armored Flexible Cable Leads-Ceramic Band Heaters -Style 10

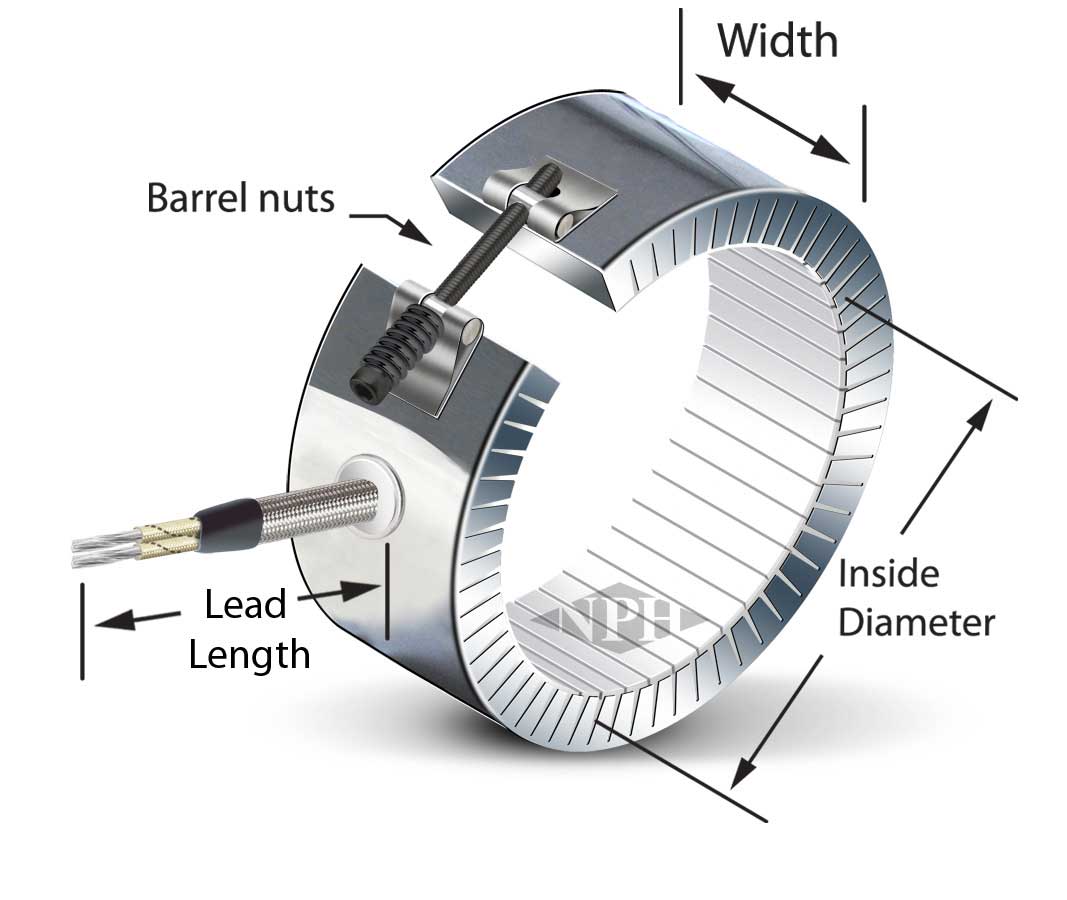

Stainless Steel Braided Leads-Knuckle Band Heaters -Style 11

Ceramic Band Heater 1 Pc. Construction with -Ceramic Terminal Covers - Style 12

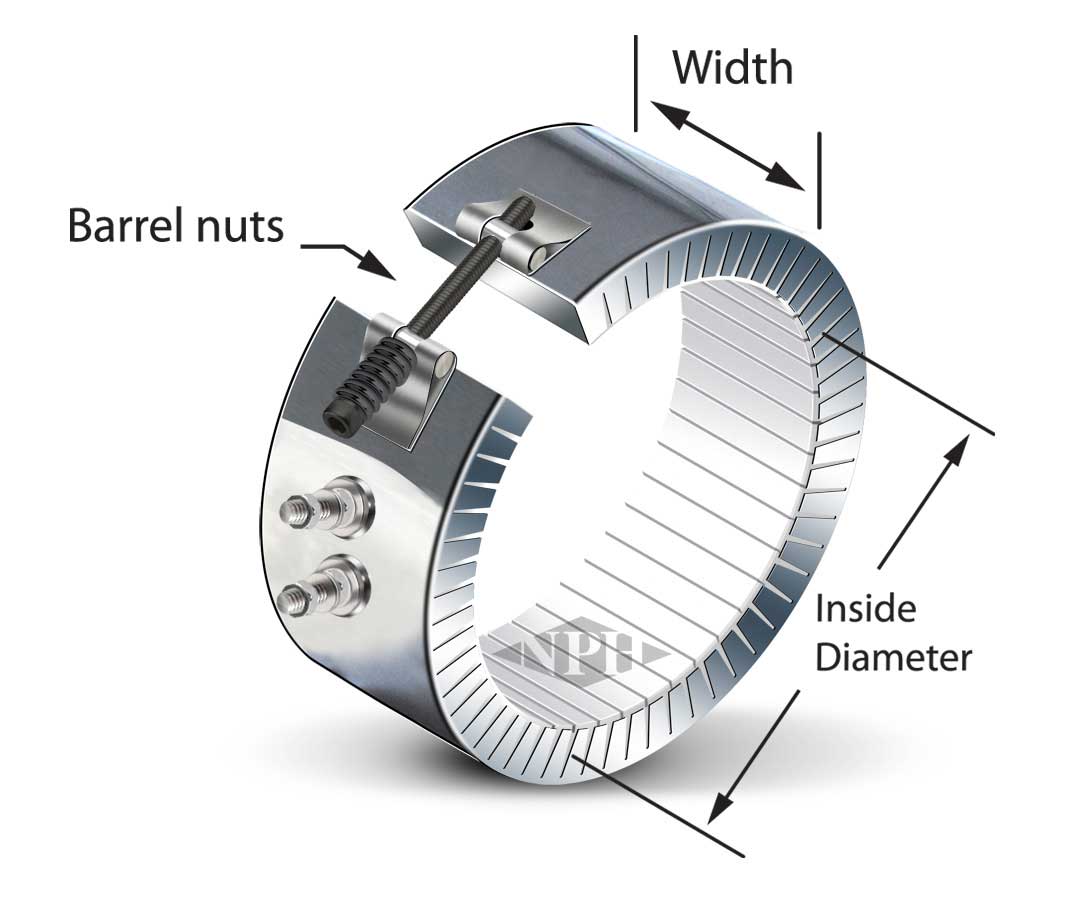

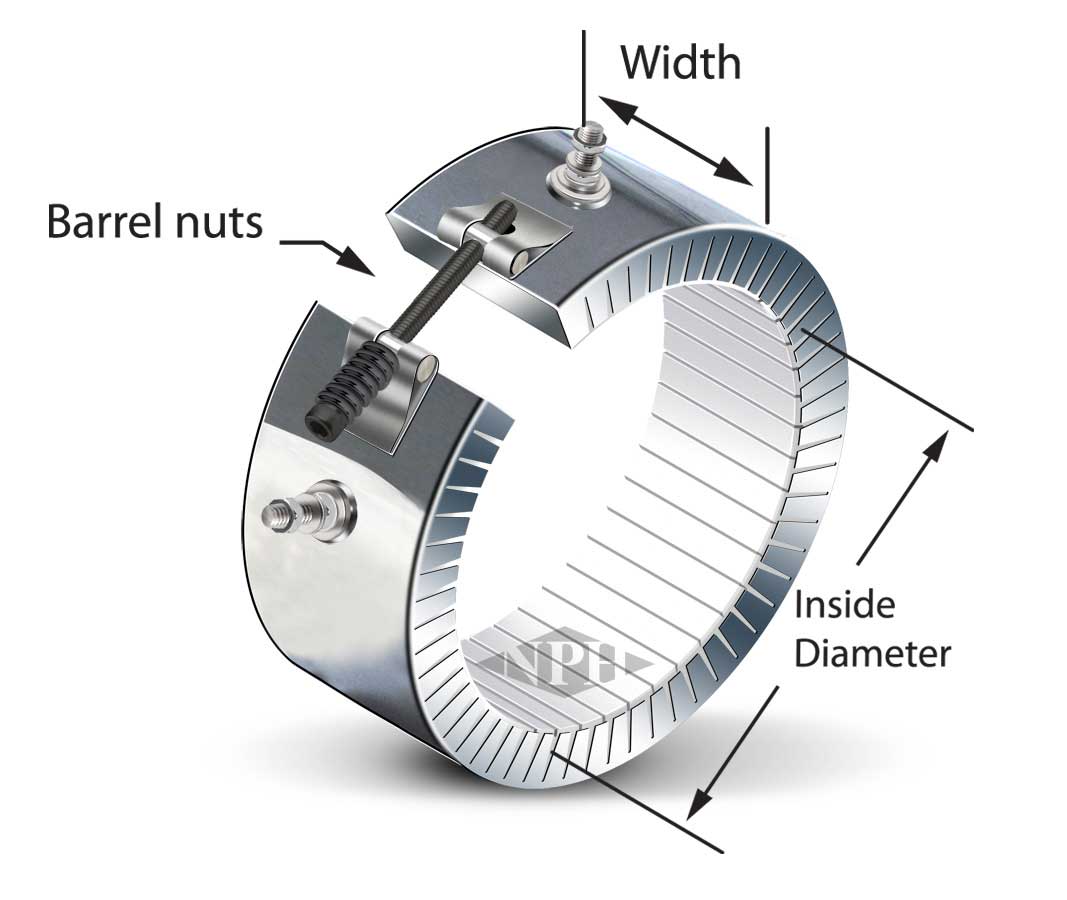

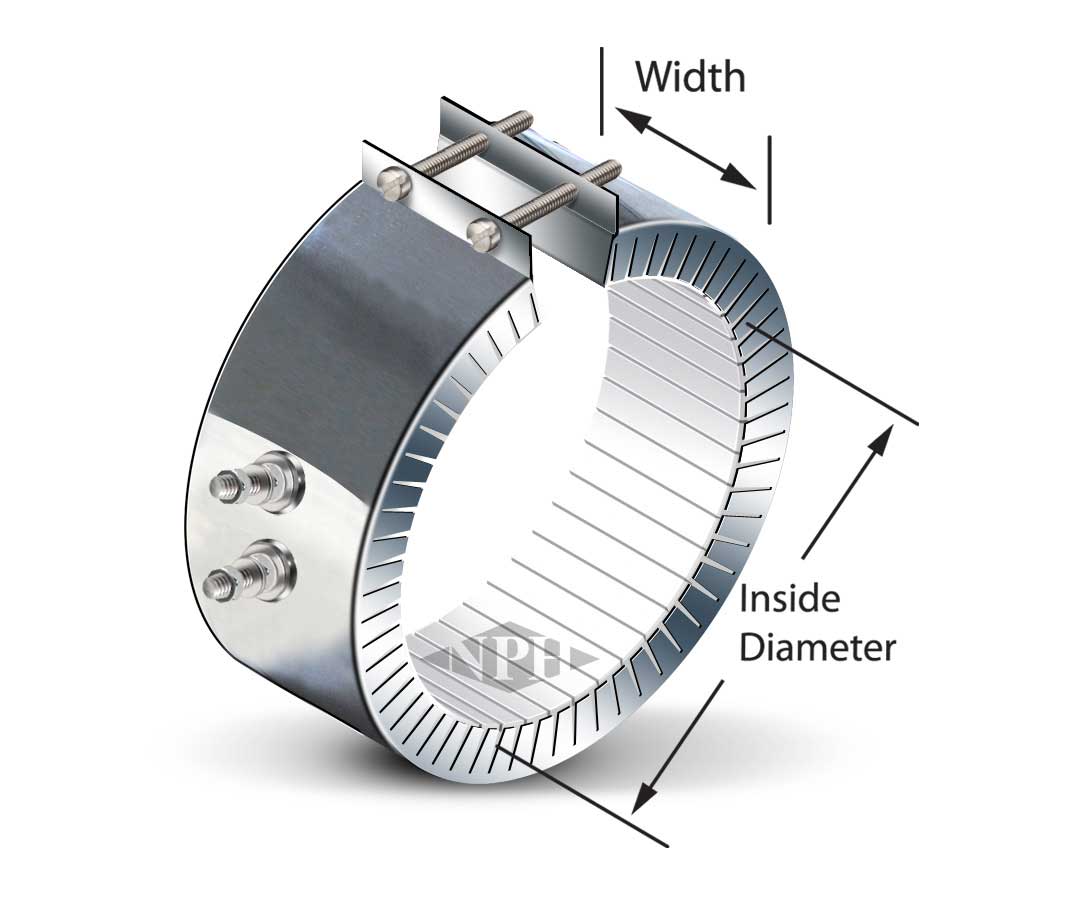

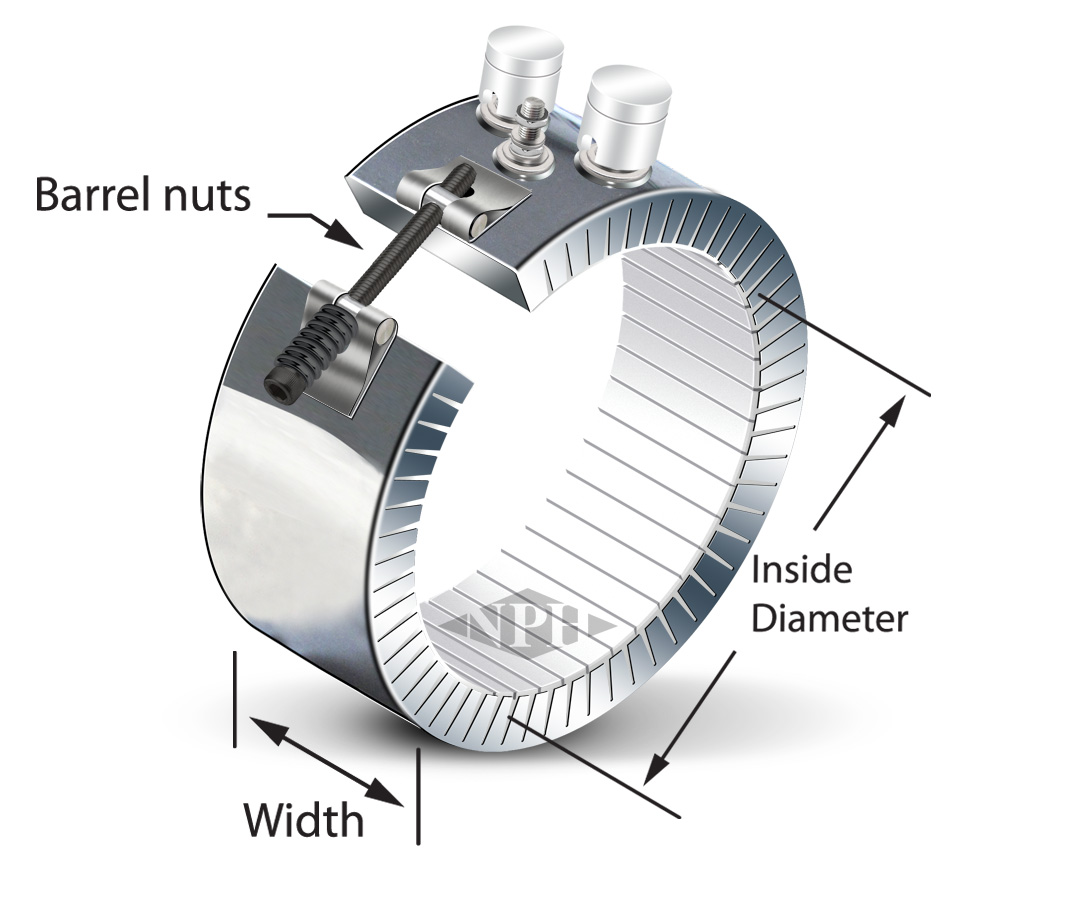

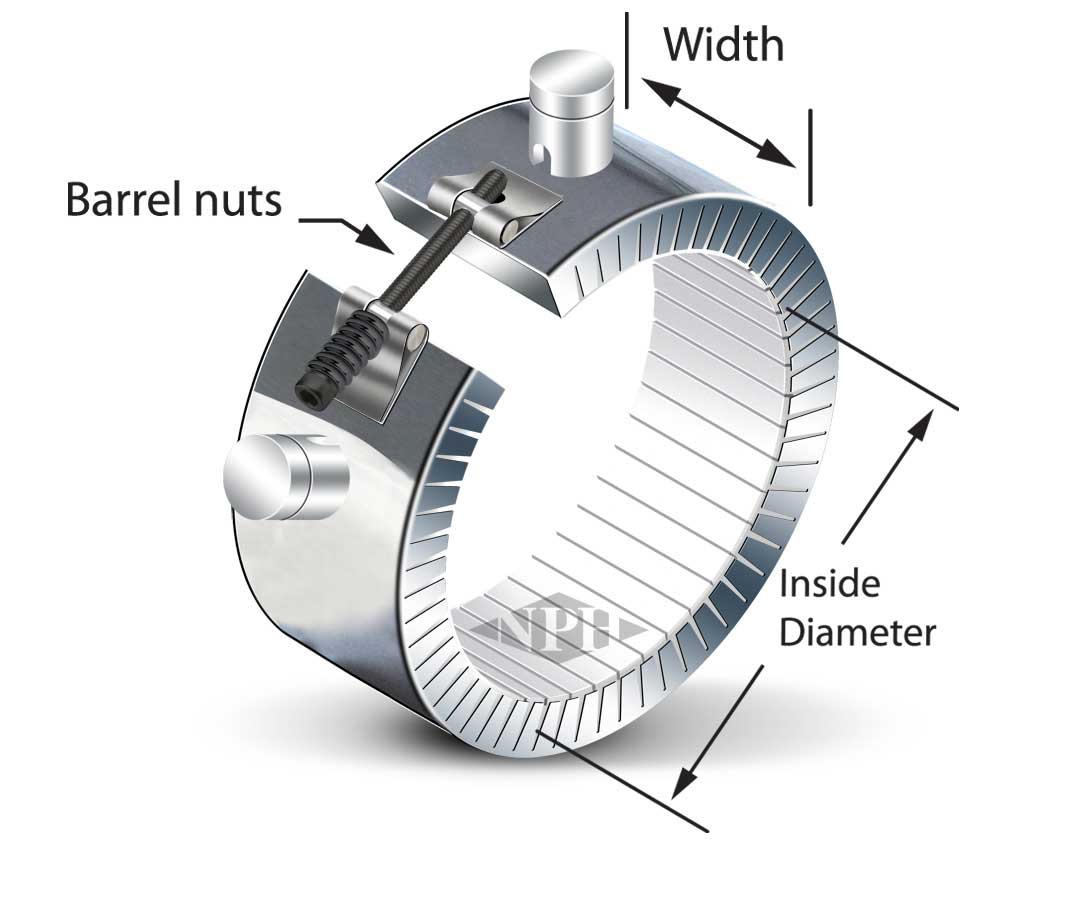

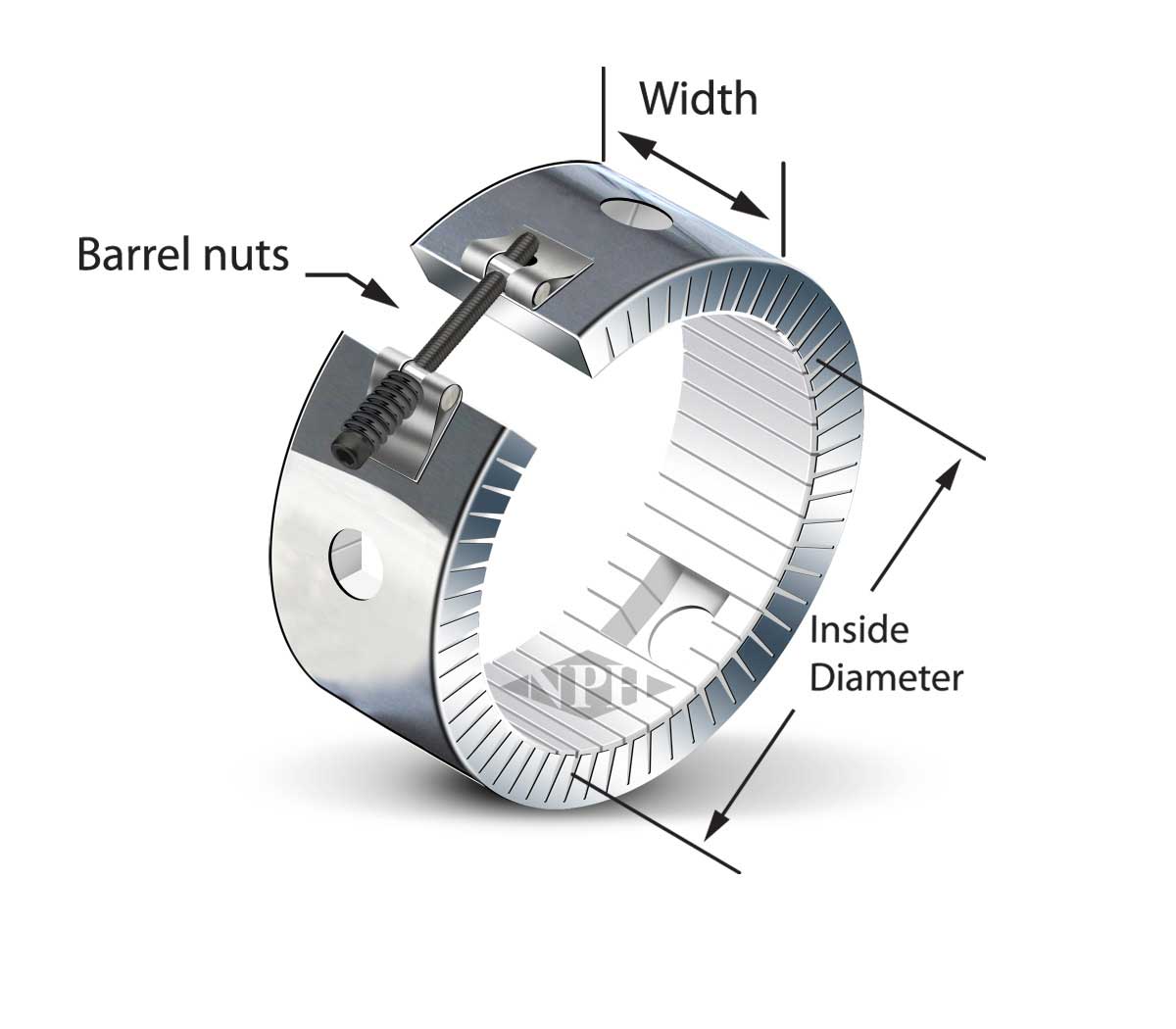

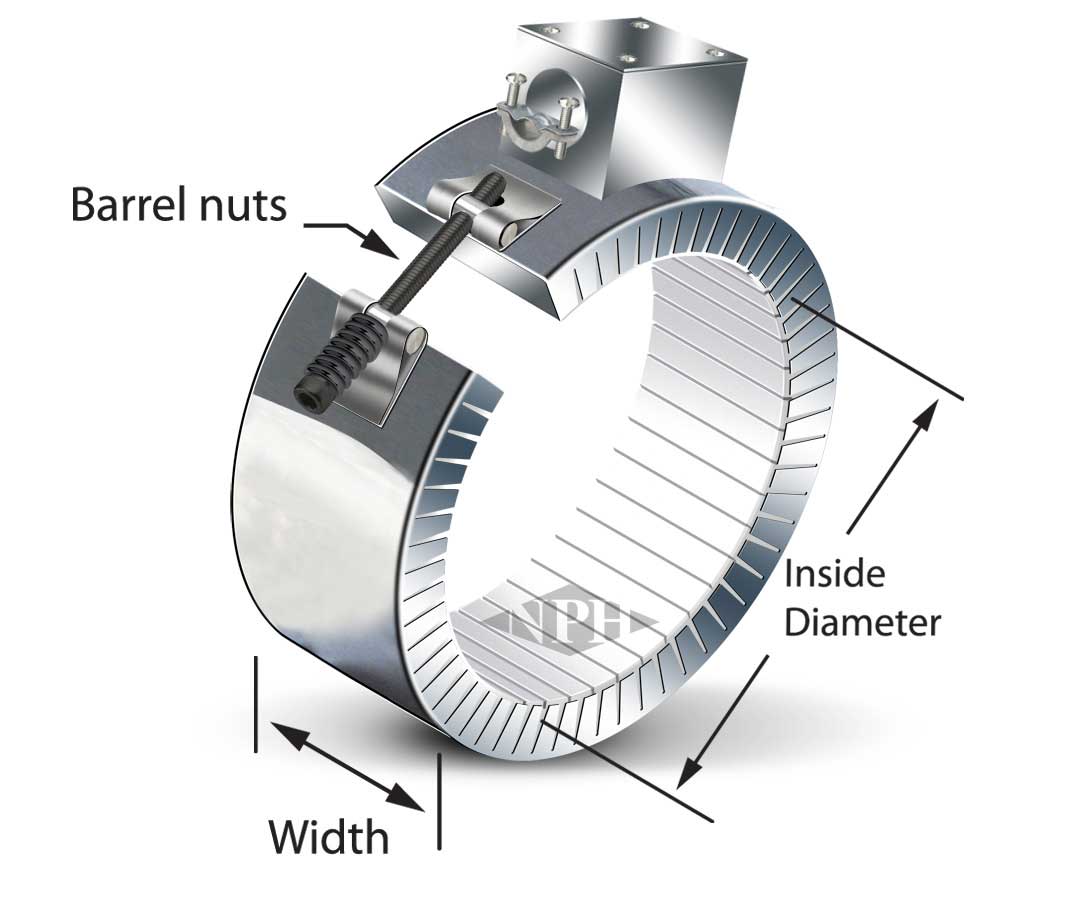

Ceramic Band Heaters with Holes Barrel Nuts -Style 13

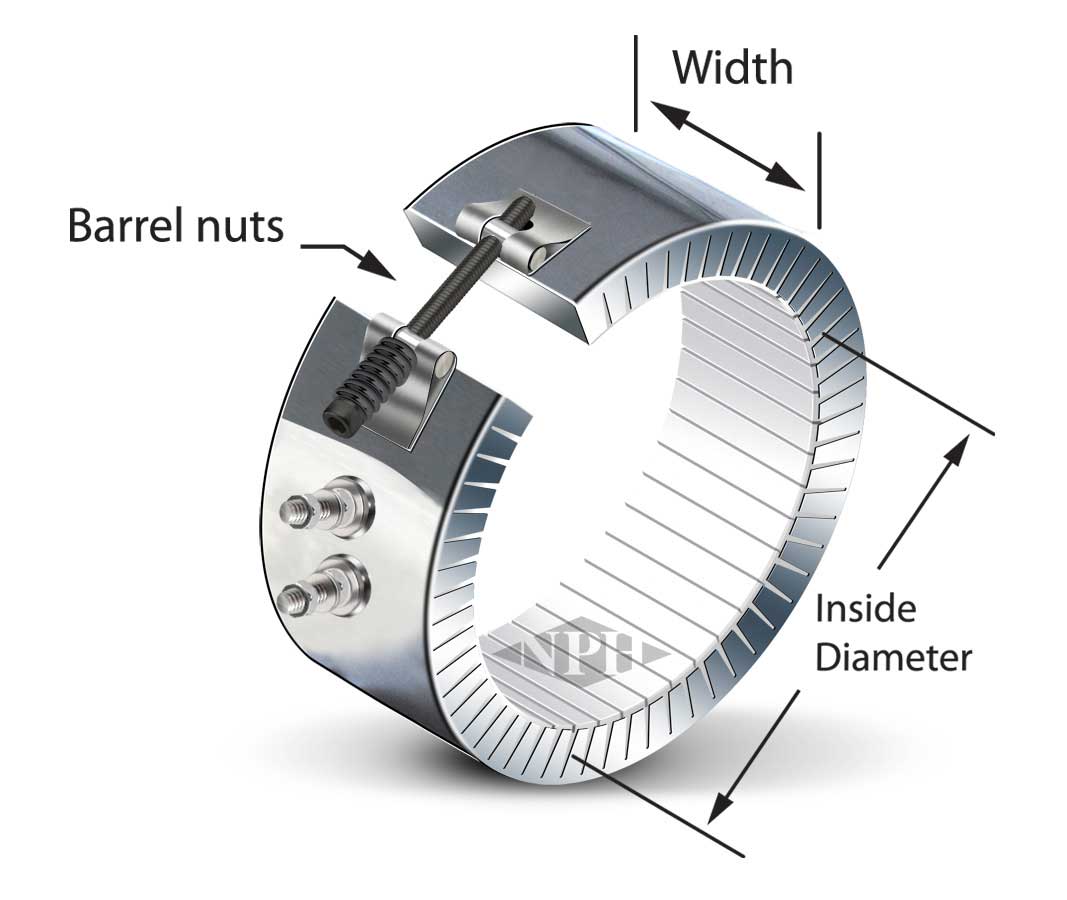

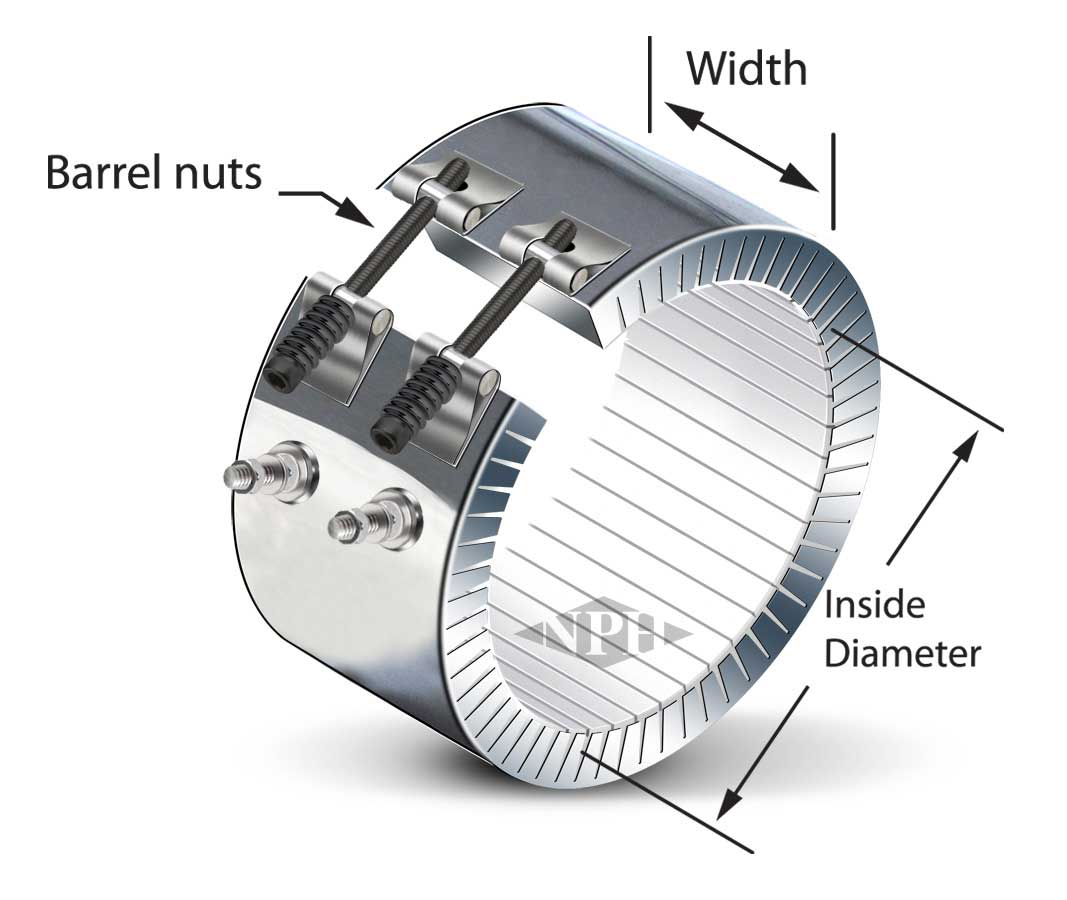

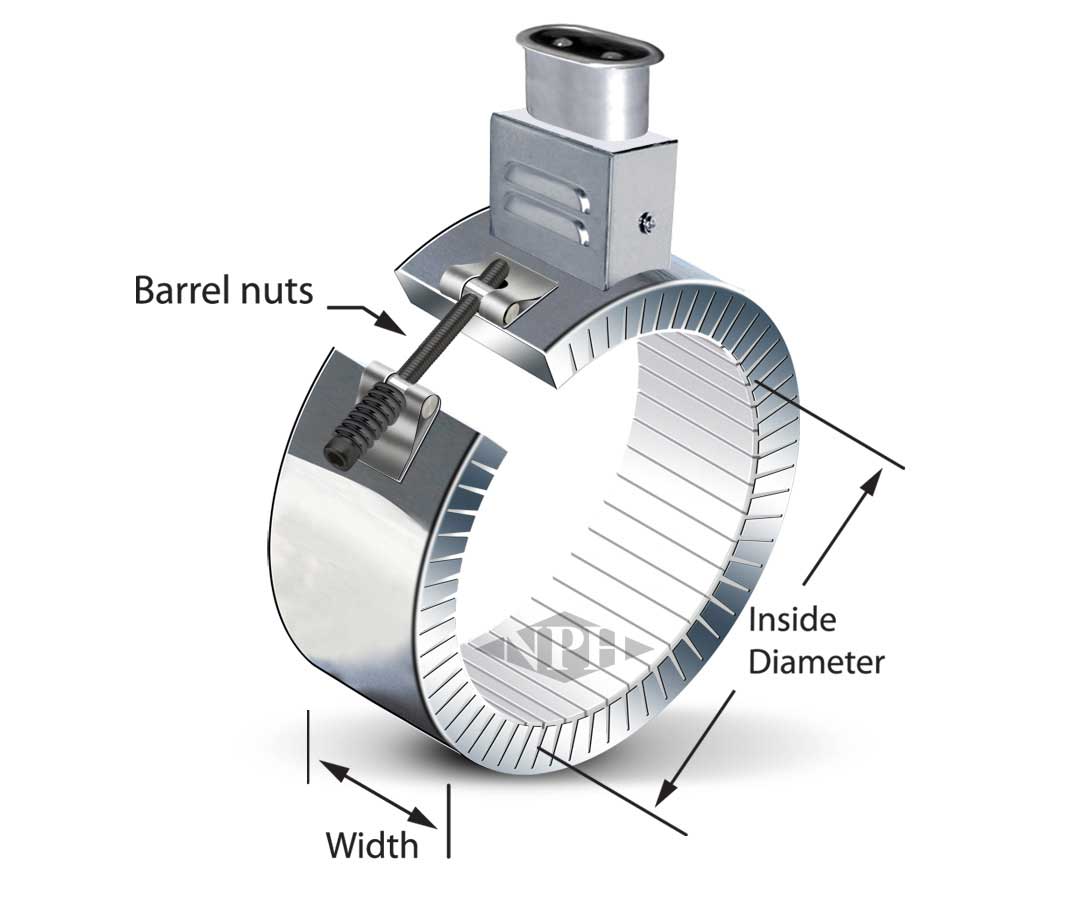

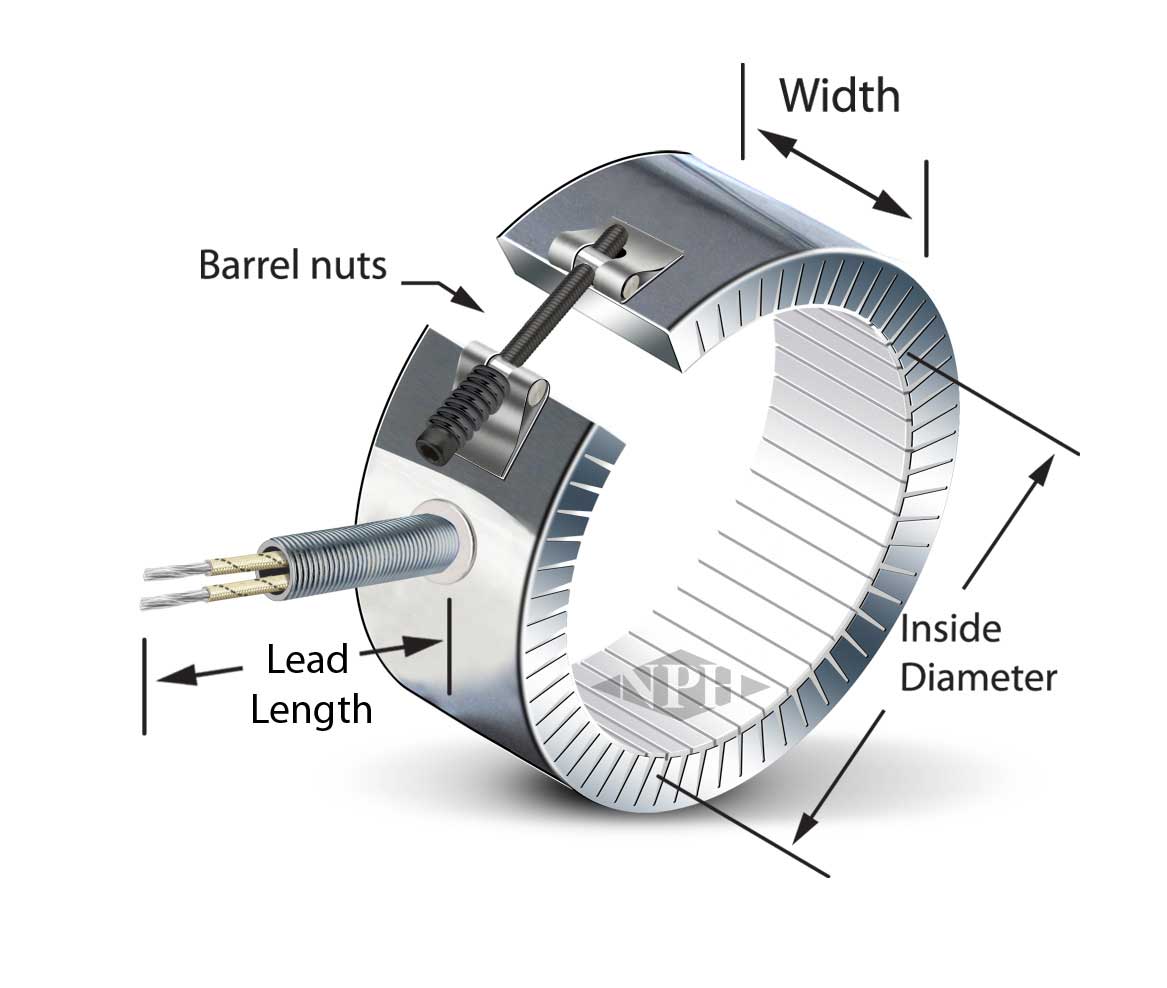

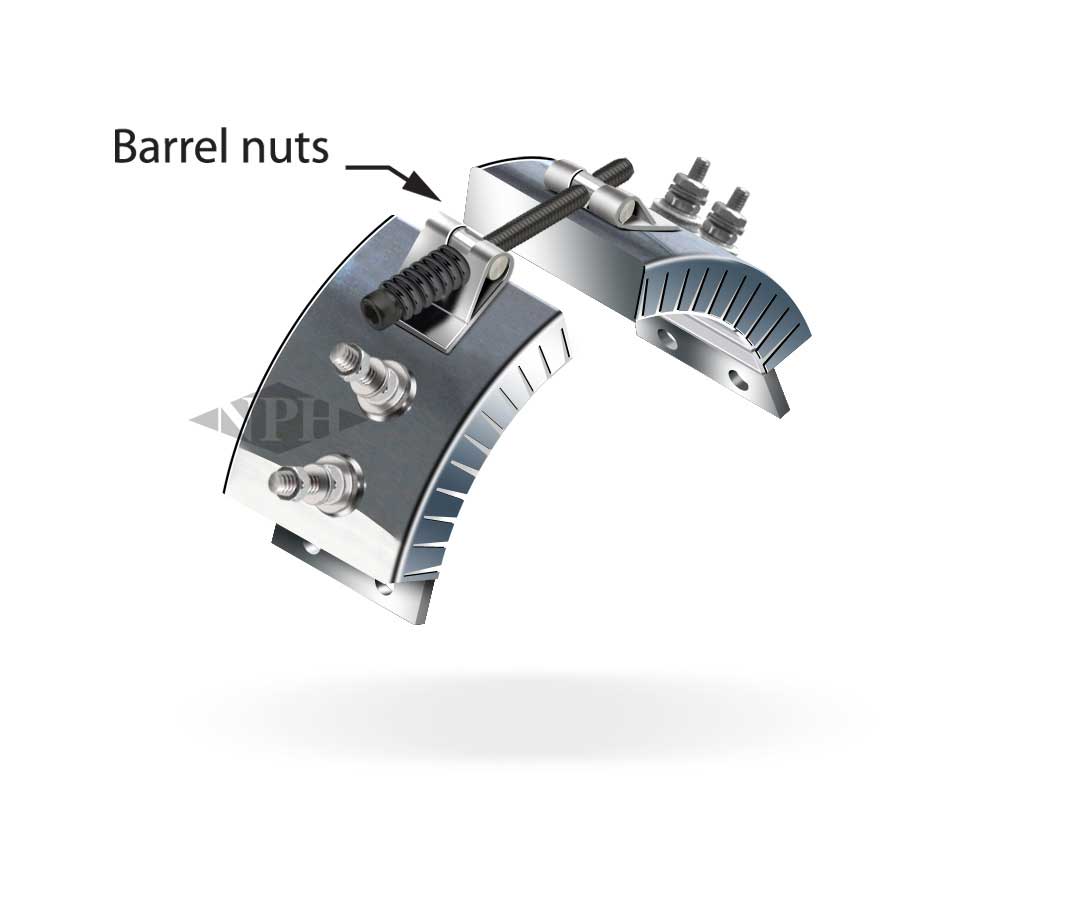

Spring Loaded Closure with Barrel Nuts- Knuckle -Band Heaters - Style 14

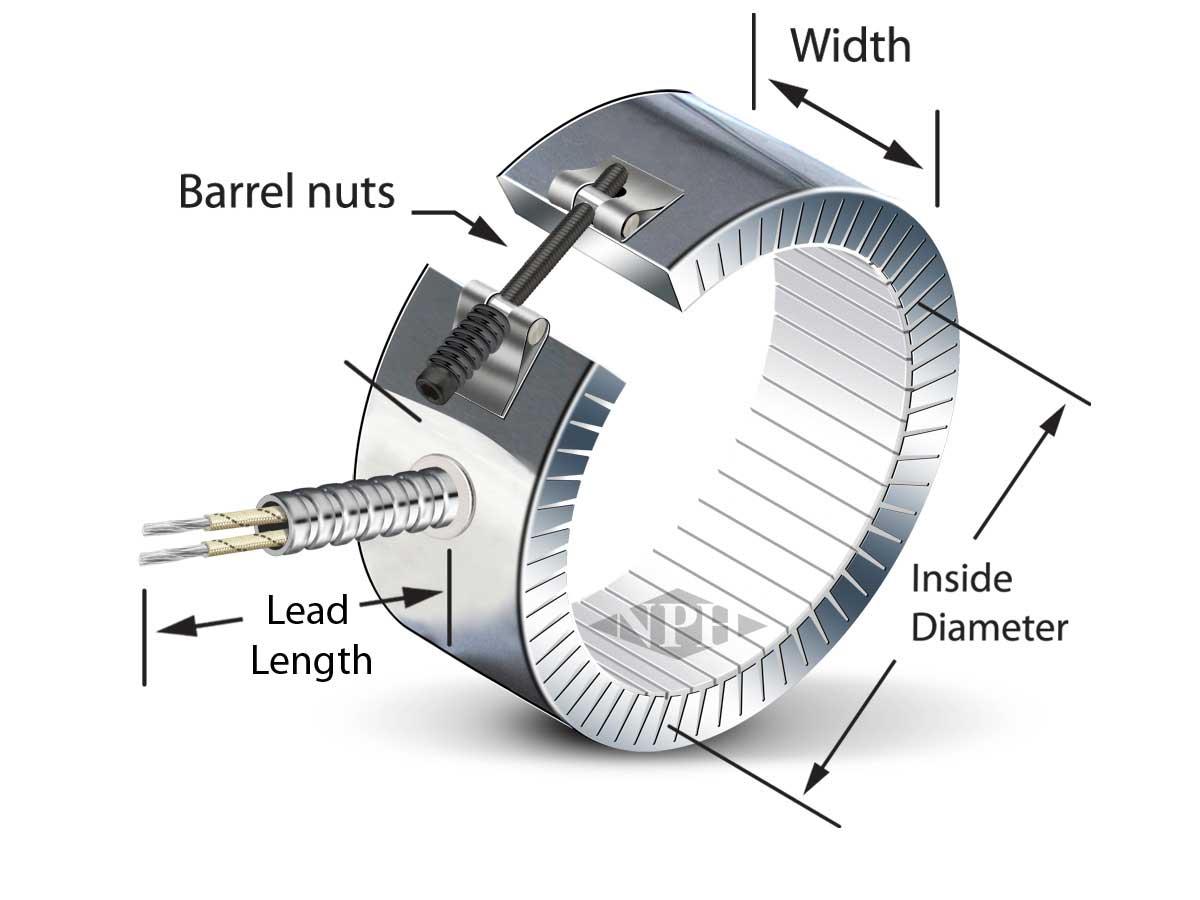

Fiberglass Leads with Strain Relief Ceramic Band -Heaters - Style 15

Right Anlgle Lead Exit with S.Steel Armor Ceramic -Band Heater - Style 16

Partial Coverage Ceramic Band Heaters - Syle 17

Sheet Metal Terminal Box -Ceramic Band Heaters -Style 18

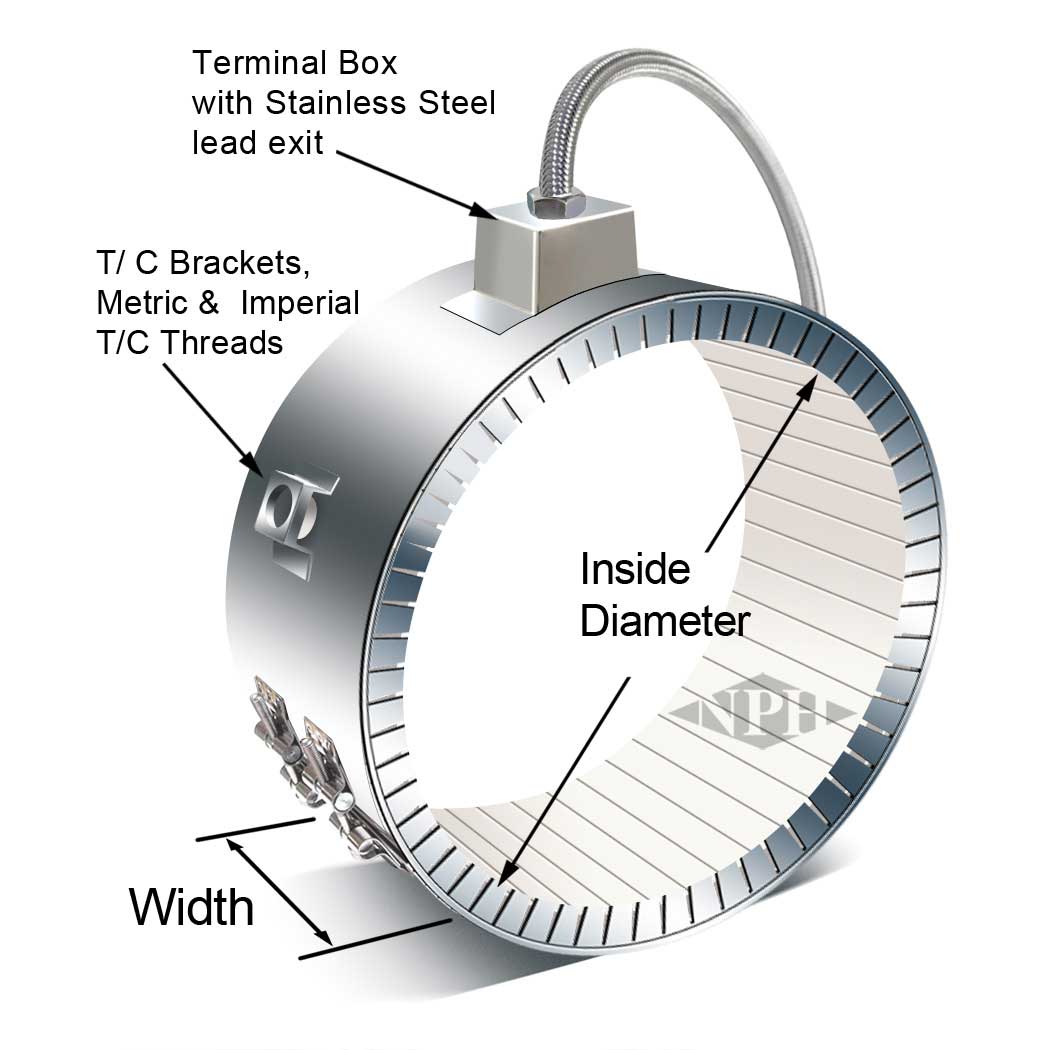

Ceramic Band Heaters with Thermocouple Bracket -S.Steel Braid Leads - Style 19

Ceramic Knuckle Heater with Shell Overlap and Hole -Style 20

Air Cooled Ceramic Band Heaters/Systems -Style 21

Closed Version-Air Cooled Ceramic Heater with Fan -Style - 22

Air Cooled Ceramic Heater with Ceramic Insulated -Beads on Leads - Style 23

Terminal Box Ceramic Air Cooled Heaters -Style - 24

Latch & Trunion Closure-Ceramic Heater -Style 25

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide