Cast-In Aluminum Heaters, Davis Standard Cast-In Replacement Heaters For Extruder Barrels, Dies & Other Custom Applications

Cast-In Aluminum Extruder Barrel Heaters, Davis Standard Replacement Extruder Heaters, Custom Cast-In Extrusion Heaters

Cast In Aluminum Extruder Barrel Heaters-Description Guide:

Heat Only Designs: Cast-In Aluminum Extruder Barrel Heaters:

Although not a common design, heat only cast-in aluminum extruder heaters are available primarily with the stainless steel mounting strap option. This design is standard 1" thick and can be used with all standard electrical terminations that NPH offers.

The cast-in heat only design can be used on piping areas that are typically more difficult to heat such as elbows and joint areas. The cast-in heater can also be cast directly onto pipe elbows or other areas to produce an integral heated part in specific applications such as feed pipes or heat exchangers.

Liquid Cooled Cast-In Barrel Heaters:

Liquid cooled cast-in barrel heaters are the most common cast -in heater design used on plastics extrusion barrels. The liquid cooling tubes run symmetrical to the heater element, which provides a uniform cooling pattern across the body of the casting. This cooling function dissipates heat rapidly from the cast-in barrel allowing a tight control of the melt temperature during operation. The typical liquid cooled design features a single ½" diameter cooling tube of stainless steel or nickel alloy. The tubes can be supplied with no termination and plumbed at the location of the equipment, or other termination options such as cast-in threaded fittings can be supplied to minimize installation time.

This cast-in design is also available with a dual cooling function. Although slightly larger in thickness, this design allows for a second cooling tube assembly, which can be employed, if the initial cooling line fails due to scale build up or cracking due to corrosion.

All NPH cast-in barrel heaters are available with mounting options of stainless steel locking straps or bolt-on clamping construction. Various electrical termination options are available depending on the application or environmental requirements.

Design Features:

- Available with dual cooling for reduced downtime or increased cooling capacity

- Large .430 diameter heating element with large cold pin for rugged termination

- Customized cooling tube options for specific applications

- Mounting to cast-in barrel can be bolt-on or strap-on design

Air Cooled/Finned Bespoke Cast-In Aluminum Barrel Heaters:

Finned/Air Cooled Aluminium Alloy Heaters

Cast-in Aluminum Air Cooled Heaters

Finned air-cooled cast-in designs provide effective heating and cooling for plastics extrusion barrels. The fin pattern can be supplied as a standard height of 1" or manufactured to a low profile thickness for small extruders or applications requiring rapid cooling.

This pattern is designed to allow the optimal airflow around the casting for maximum cooling rates. Typically the forced air for the cooling function is driven by a shroud and blower system that is an integral part of the extruder, however these cast- in heaters can be utilized with an individual shroud and blower assembly for increased cooling control of the individual heater zones.

All NPH cast-in barrel heater designs are available with mounting options of stainless steel locking straps or bolt-on clamping construction. Various electrical termination options are available for the air cooled cast-in heater depending on the application and environmental requirements.

Design Features:

- Cast-In with various fin patterns for maximum airflow distribution

- Available with low profile cast-in fins for space restricted designs

- Mounting to cast-in barrel can be bolt-on or strap-on design

- Wide variety of heavy duty electrical termination options

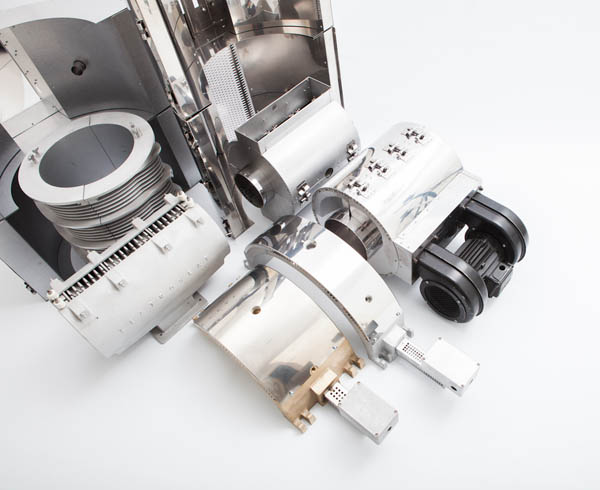

Air-Cooled With Blower and Shrouds Cast-in Heaters:

Finned/Air Cooled Cast In Aluminum/Bronze Heaters with Blowers and Shrouds

Individual shroud and blower systems can be used with finned barrel heaters as self contained systems on extruder barrels. The shrouds are manufactured as cast aluminum with bolt mounting or a hinged clamshell design fabricated from stainless steel .

The internal design of throat maximizes the airflow over the finned heater body for rapid cooling. Each shroud has a reinforced mounting platform at the orifice for standard sized blowers. Custom mounting options and sizes are available for custom blower applications.

Design Features:

- Shrouds are manufactured as cast aluminum, stainless steel or bronze

- Internal air deflector system for maximum airflow

- Vertical or horizontal mounting platforms for blowers

- Custom mounting platforms for customer supplied blowers

- Manufactured to support standard 145CFM to 495CFM blowers

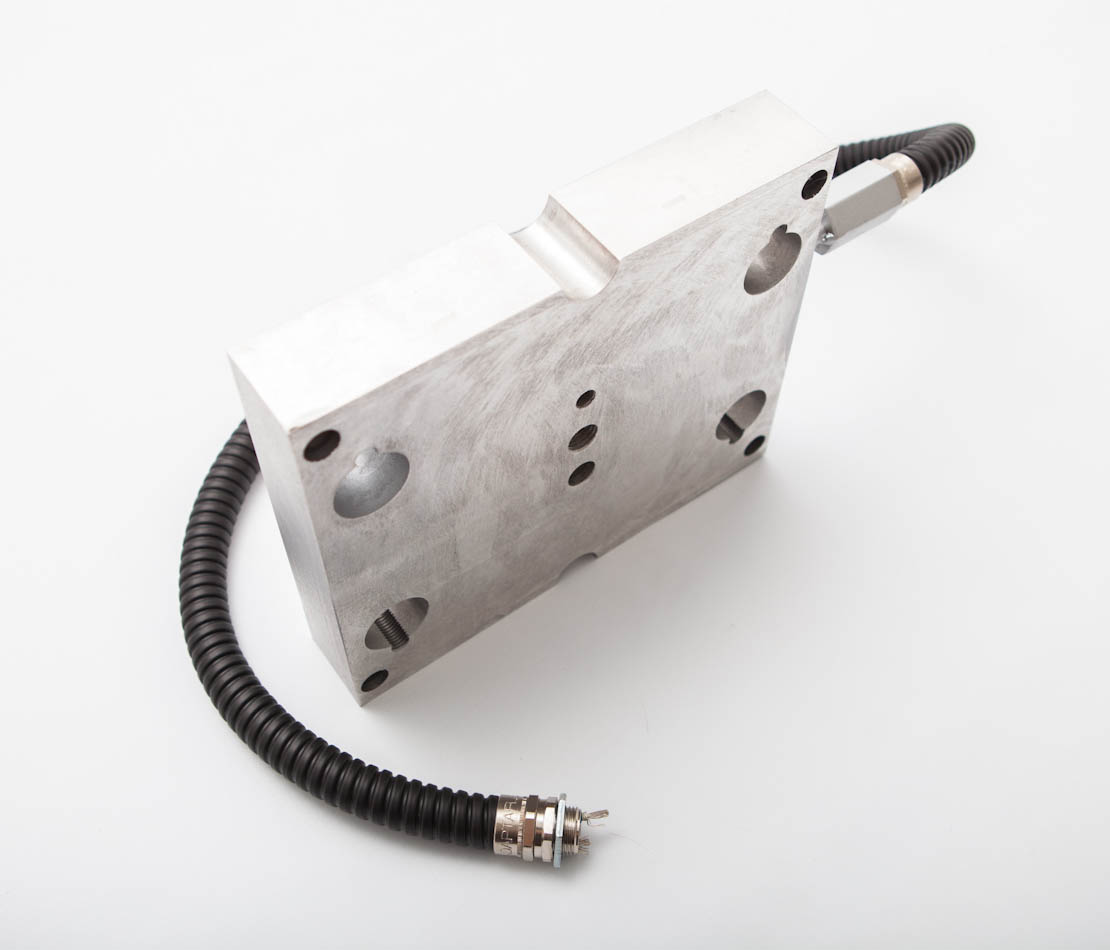

Vents or Cut-outs Cast-In Aluminum

Heaters:

Special sections of the cast-in extruder barrel such as a vent or feed throat require custom

modifications to fit properly.

These Vent/Cutout Cast-In Heaters are designed with element locations that maximize heater

performance, but allow for special machined sections that could not be added to a standard

barrel design.

Design Features:

- Available in aluminum or bronze

- Manufactured per customer specification

- Available with all standard terminations

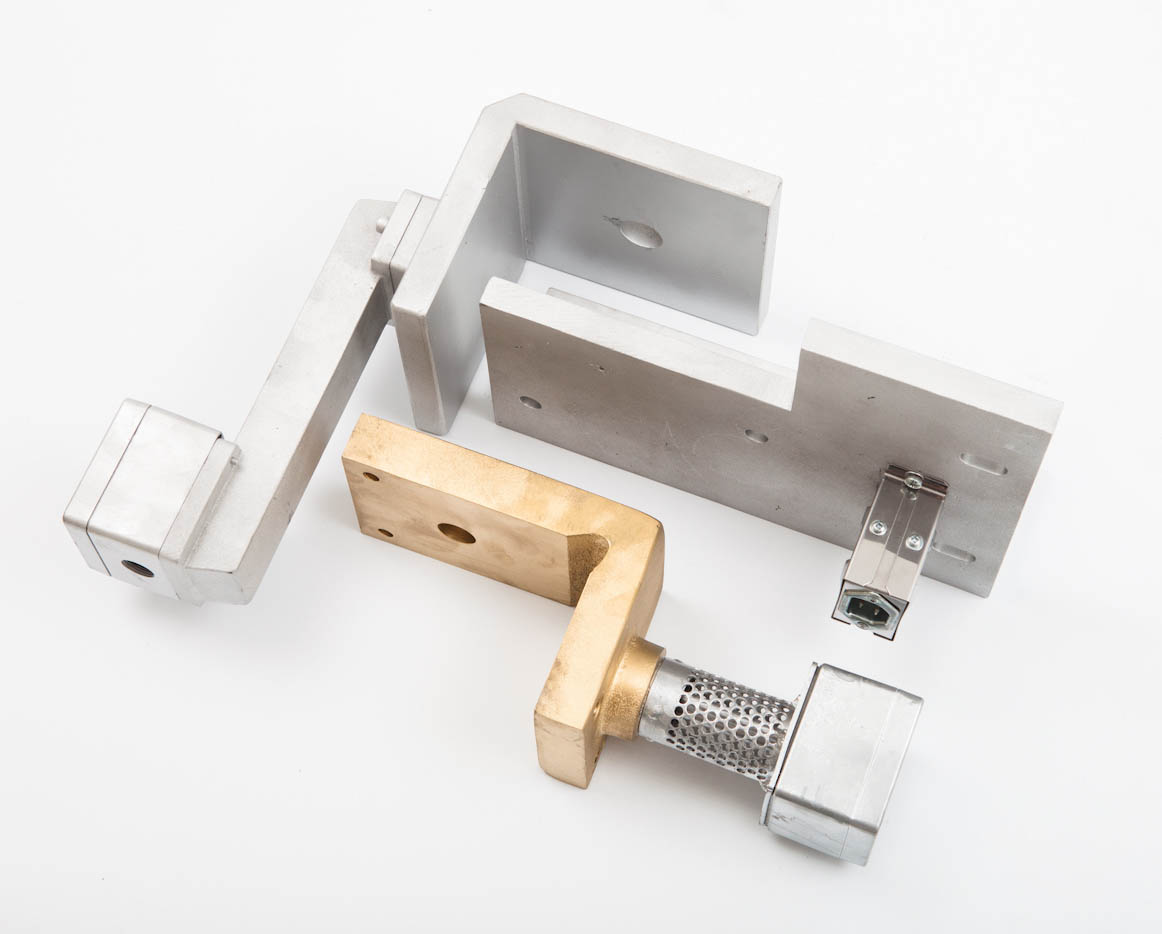

L Shaped Square Cast-In Barrel Heaters:

L Shaped Cast Aluminum and Cast In Bronze-Extruder Dies

Aluminum Platens for Various Applications

The "L" shape cast-in heater design is typically used on square and rectangular extruder barrel dies, which utilize a twin, screw design. In most cases, the high operating temperatures in these applications require these cast-in heaters to be constructed of a bronze alloy, however aluminum alloys are used for applications, which do not require the higher watt densities.

While the most common design for "L" shaped cast-in heaters consists of heat only, they can be manufactured with cast-in cooling tubes. Typical mounting options include manufacturing the casting with 45°mounting flange which allows the cast-in heaters to be bolted and drawn together on the barrel or the cast-in heater can be supplied with mounting holes machined into the casting to mount directly to the barrel.

The most common electrical termination for the "L" shape designs is a junction box mounted on to a vented tower that extends from the body of the casting. The box has a gasket for moisture resistance and can also be supplied with explosion proof specifications.

The junction box can also be cast directly onto the heater. High temperature leadwire with a heavy-duty bronze braid is also available upon request.

Design Features:

- Flange ear or drilled holes for mounting to the barrel

- Durable cast-in vented towers for terminal box mounting

- Manufactured in aluminum alloy for lower temperature applications

- Cooling tubes can be cast-in for liquid cooling capacity

- Machined holes for transducers and thermocouple locations

Custom Cast In Aluminum Heaters - Specifications:

Size. . . . . . . . . . . As required any Size possible

Voltage. . . . . . . . 120, 240, 480, or 600 volts

Phase. . . . . . . . . Single or Three phase available

Termination's. . . . Leads, Terminal Boxes, Screw/Threaded Studs

Machining Tolerance. . . . 005" Standard 2

Wattage. . . . . . . . Aluminum Up to 35 W/in2 Bronze Up to 50 W/in

Maximum Temperature. . Aluminum 700 degrees F Bronze 1400 degrees F

Options. . . . . . . . . . Holes, Grooves, Notches, Cutouts, Available

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide