Boiler and Thermolator Immersion Heaters, (Non ANSI) Heaters:

Product Description-Boiler and Thermolator Heaters:

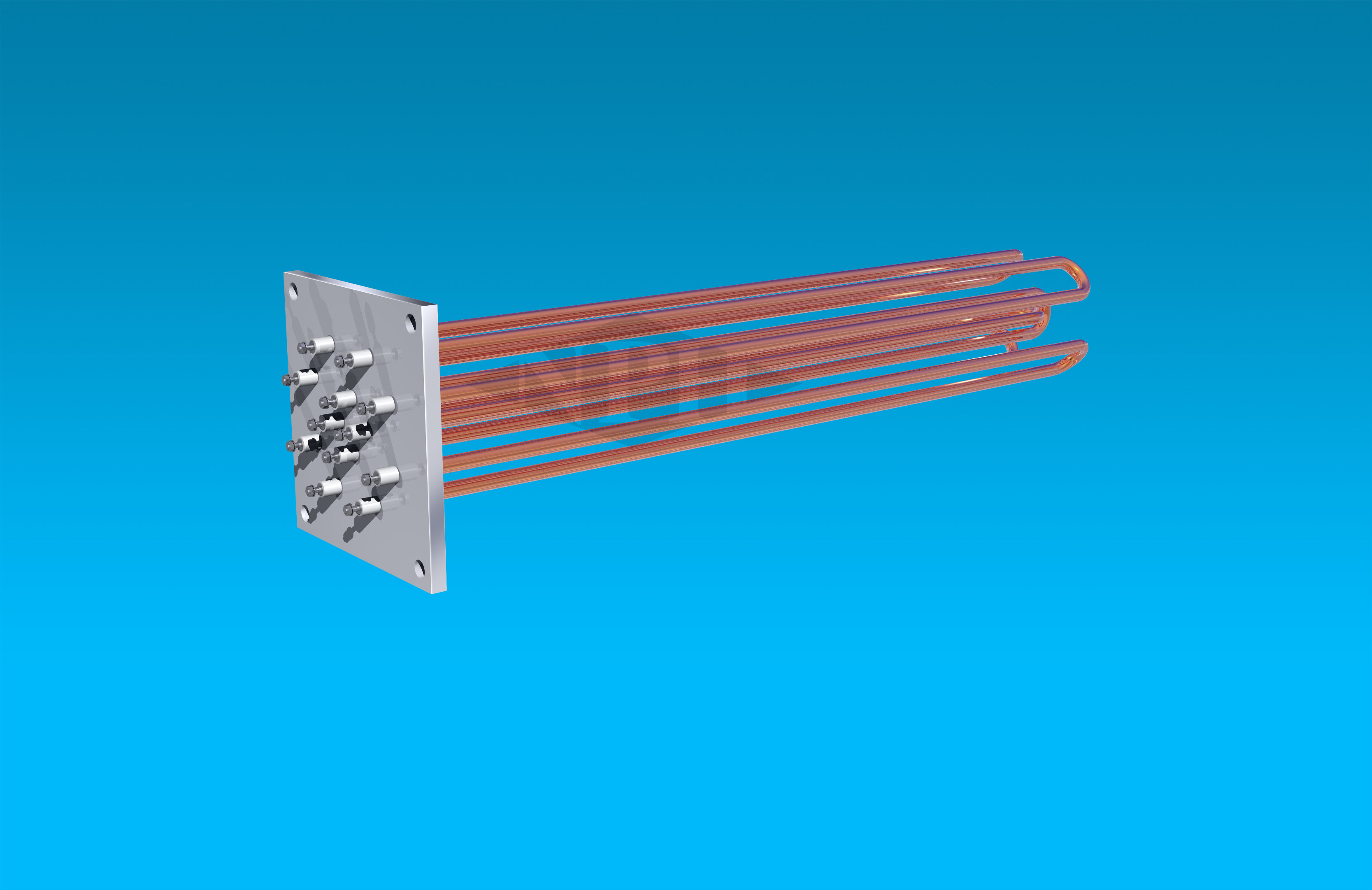

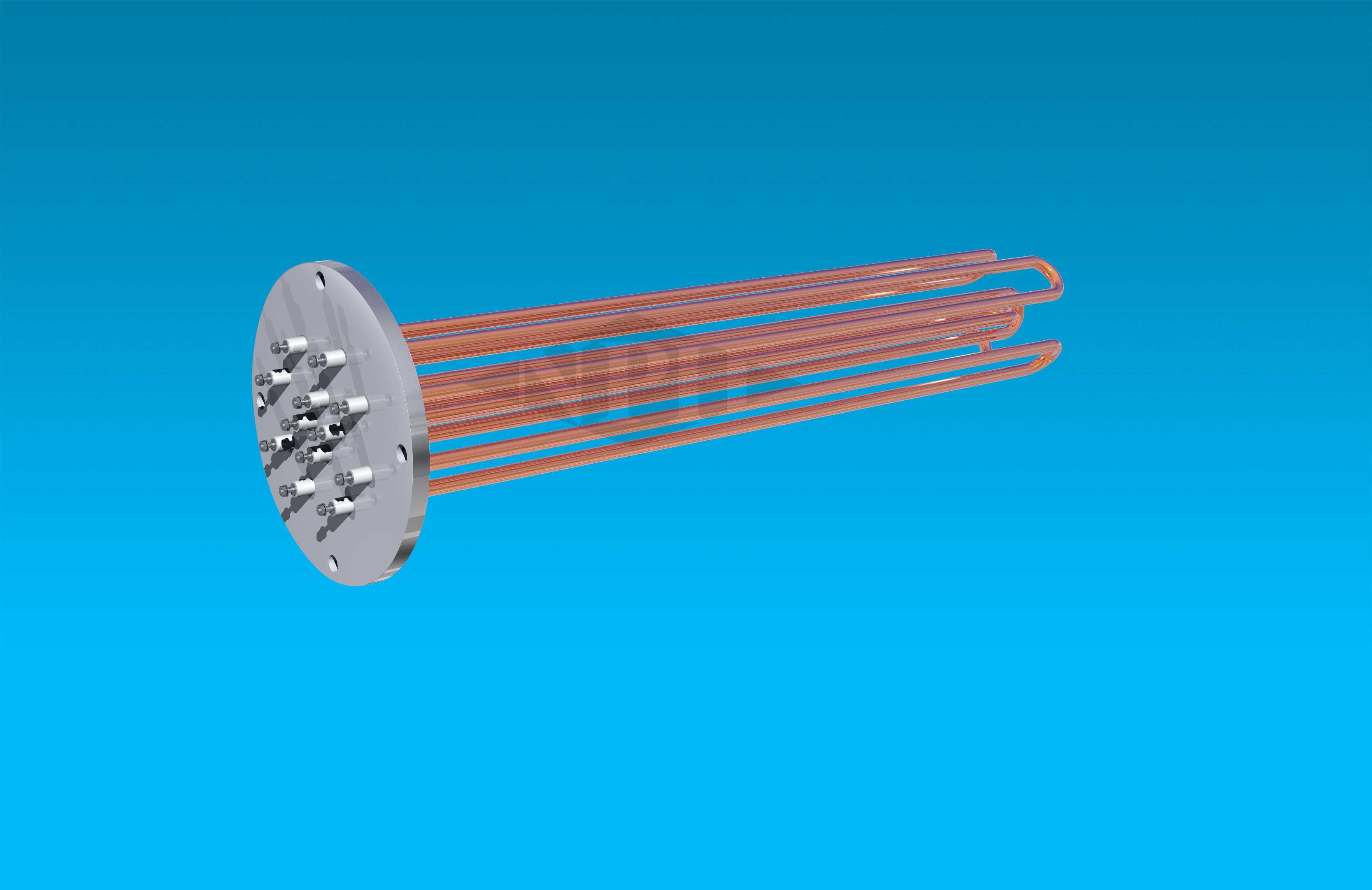

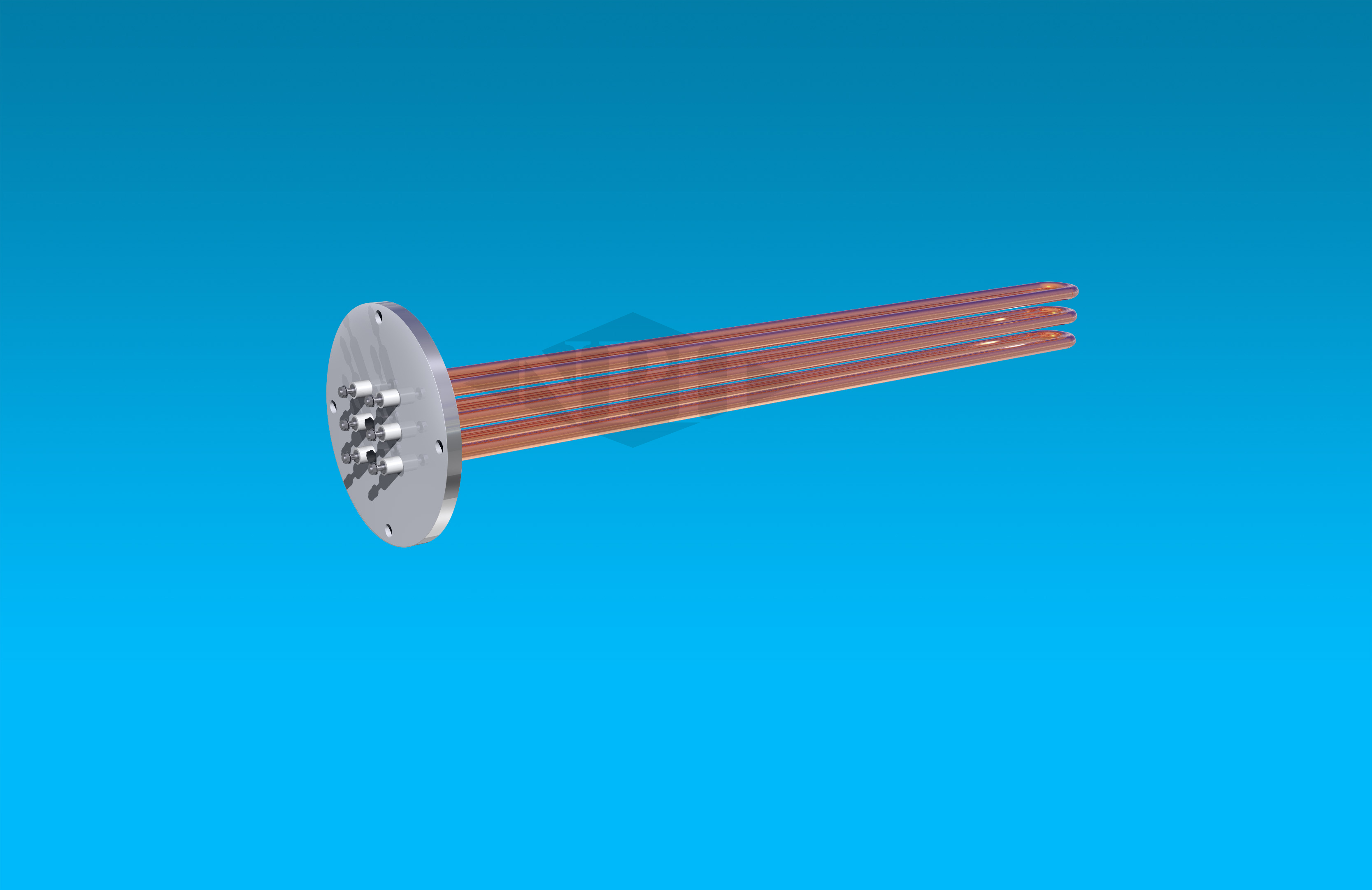

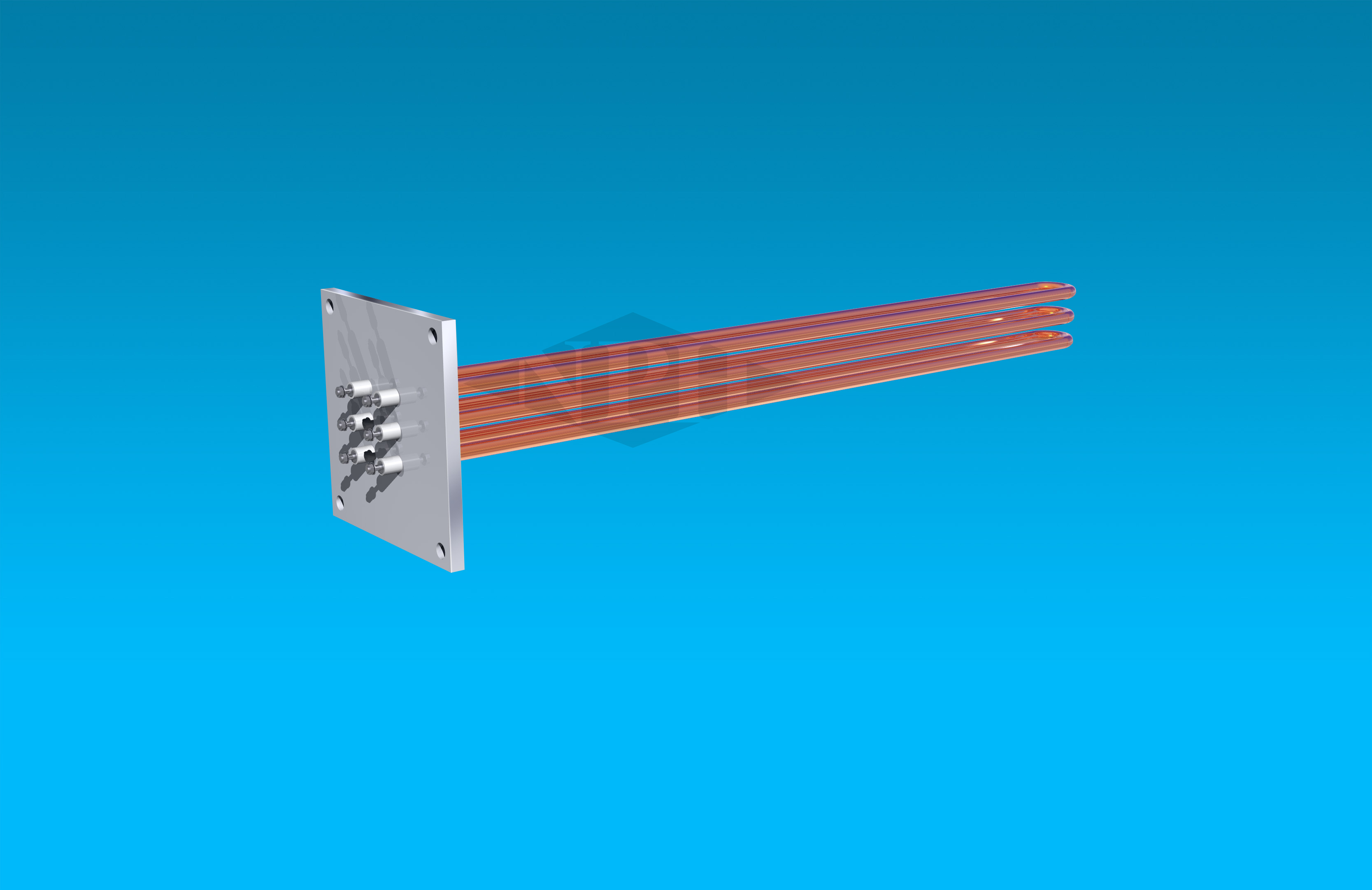

Square and round steel flanged electric immersion heaters are a great choice for applications requiring fast efficient electric heat. Often used as direct replacements for boilers, water storage equipment for thermolators and as standard water heaters. These heaters are available in a wide selection of rates, sizes and sheath materials. Boiler heaters are very efficient since all energy that is generated is dissipated directly to the medium which is being heated. The high watt density allows rapid heat transfer to the process. Epoxy seals provide moisture protection for the elements. All boiler and thermolator heater models incorporate tubular heater construction welded or brazed into a carbon steel flange.

Standard boiler heaters are available in 120V, 208V, 240V and 480 V units. Single phase and three phase options are available. To guarantee sheath material and watt density compatibility with material or process being heated consult NPH. All of our boiler and thermolator heaters are CSA/NRTL and UL approved.

Boiler Thermolator Heaters:

Our fluoropolymer (PTFE) immersion heaters are compatible with virtually any chemistry and are available in sizes up to 18 kilowatts, single or three phase. We offer a large variety of standard and custom configurations for over-the-side and tank bottom installations, and low profile custom designs are also available. Rigid and flexible risers available. Our screw plug and flange heaters are manufactured in sizes from ½-inch screw plug (100 watt) to 6-inch flange (18 kW). Thermal overtemperature protection standard (except screw plug), and we offer rigid and flexible risers. The vast majority of our immersion heaters are cULus and CE.

Boiler and Thermolator (Non ANSI) Heaters: Specifications, Manuals, Technical Letters & Tips:

|

|

|

|

- Hot Water Storage Tanks

- Warming Equipment

- Heating & Preheating All Grades of Oil

- Cleaning and Rinsing Tanks

- Heat Transfer Systems

- Boiler Equipment

- Freeze Protection of Fluids

- Petro-Chemical

- Oil Heating Loops

Standard Construction Features:

Elements Materials — Copper, Steel, 304/316 Stainless Steel, Incoloy

Number of Elements in Flanges — 3 and 6,

Element Diameter — 0.315" – 0.430"

Watt Density — 6.5, 15, 23, 45, 75W/in2

Flange - Materials - Carbon Steel, Stainless Steel,

Flange Rating – NON ANSI Flange

NON ANSI Flange Sizes Square - 4 ½" and 5 ½"

NON ANSI Round Flanges- Custom Sizes

High Conductivity Elements -

Filled with highest purity blends of magnesium oxide refractory (MgO) compacted to rock hard density to insure maximum thermal conductivity and maximum electrical resistance, and assure long element life.

Heavy Coil Construction - Watt density on the heating coil is designed for low watt density operation by increasing the coil diameter and length to give maximum coil surface area and limit coil surface temperature, providing longer coil life.

Grounding Connector Standard - A solid terminal connector is standard on all NPH immersion heaters insuring positive ground and personal safety.

Special Features Available:

Kilowatt Ratings – 50 KW and above available

Flanges:

Materials - 316, 321, 347 stainless steel. Inconel, Incoloy

Ratings NON ANSI Flanges-Round & Square

Sizes - Please contact NPH for other materials or ratings.

Elements Materials - 316, 321, 347 stainless steel. Inconel. Other materials available, please contact NPH

Other Features - Underwriters Laboratories U.L./CSA listing available. Consult NPH.

National Plastic Heater Corrosion Policy:

NPH cannot warrant any electric immersion heater against failure by sheath corrosion if such failure is the result of operating conditions beyond the control of the heater manufacturer. It is the responsibility of the purchaser to make the ultimate choice of sheath material based on his knowledge of chemical composition of corrosive solution, character of materials entering the solution, and controls which he maintains on the process. * Not intended for use in hazardous locations.

We Ship Our Kapton & Process Heaters To OEM’s & Industry World Wide